-

As a laboratory equipment manufacturer specializing in the development and manufacture of stainless steel reactors

and other products, TOPTION has a global reputation for excellence in quality, innovative technology, and excellent service. Through continuous investment in research and development and close cooperation with our customers, we promote innovation and development in scientific research and industrial production. -

-

Global Stainless Steel Reactor Market Size and Growth Trend

In recent years, the stainless steel reactor market has shown steady growth. Driven by the demand in scientific research, chemical industrial production, drug manufacturing, and food processing, the equipment maintains a steady growth or gradually expanding demand in the global market.

-

Wide Application of Stainless Steel Reactor

Stainless steel reactors are widely used in the chemical, pharmaceutical, and food industries. In the chemical industry, stainless steel reactors are commonly used in the synthesis and polymerization process of various chemical reactions. Its stable reaction effect and excellent environmental conditions significantly improve the synthesis efficiency of many chemical products. In the pharmaceutical industry, stainless steel reactor is commonly used in drug synthesis and intermediates preparation processes. It has high temperature and high-pressure performance to meet the requirements of the pharmaceutical industry for harsh reaction conditions. In addition, in the field of food processing, stainless steel reactors are widely used in processes such as mixing, fermentation, and flavoring. With consumers’ pursuit of healthy food and individual tastes, the demand for stainless steel reactors is expected to continue to grow.

-

-

Upholding the core values of innovation, quality, and customer satisfaction, TOPTION offers a wide range of models of laboratory reactors (5L, 10L, 20L, 30L, 50L, 100L), pilot reactors (150L, 200L, 300L, 500L) as well as customized industrial-grade, large-capacity (over 1000L) stainless steel reactors. Whether it is a scientific research institution, chemical enterprise pharmaceutical company, or food processing industry, we can provide you with stainless steel reactors that meet your requirements and become your reliable partner.

-

-

Advantages of TOPTION stainless steel reactors

·Corrosion resistance: We use high-quality 304 or 316-grade stainless steel materials to manufacture, able to resist corrosive substances such as acid and alkali erosion, to ensure the quality of experimental products and the service life of the equipment.

·Temperature controllability: TOPTION stainless steel reactor is equipped with an advanced heating and cooling system, which can accurately control the temperature of the reaction system to meet the needs of complex experimental conditions.

·High-efficiency stirring: We adopt an optimized design of the stirring structure and power system to ensure homogeneous mixing of reactants and provide a good mass transfer effect.

·Safe operation: TOPTION stainless steel reactors are equipped with multiple safety protection devices, such as over-pressure protection, over-temperature protection, and power leakage protection, which effectively reduces operational risks.

-

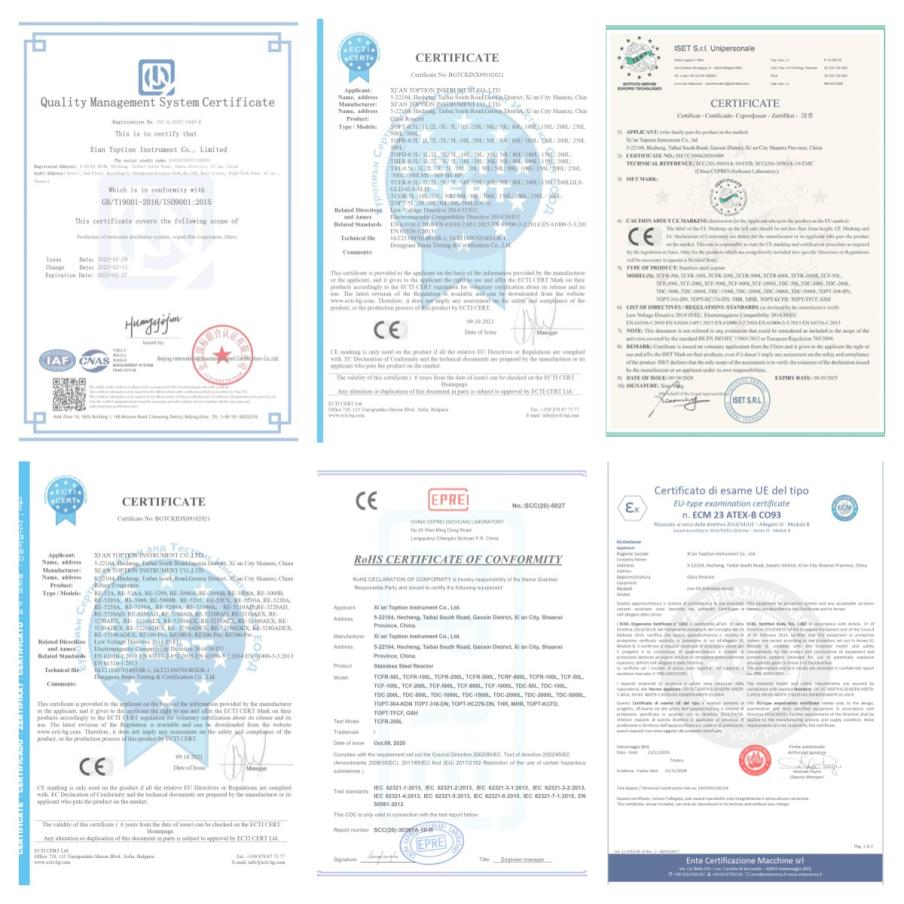

TOPTION product quality and service

All of our products have passed international certifications such as ISO, CE, UL, and SGS. In addition, we have professional business and technical teams to provide excellent pre-sales consulting and support, and excellent after-sales service characterized by quick response, problem-solving, and continuous care to ensure the highest level of customer satisfaction.

-

-