-

Sudden solvent bumping, vacuum pump being corroded, harmful gas escaping, and low receiving rate, how to avoid these problems? How to choose the right rotary evaporator?

1. The first thing we need to consider is your sample,as the different samples have different boiling points and require different temperatures to condense, so we need to match chillers / low temperature circulating bath with different temperatures ( -50℃ is ideal for water-based samples, -85℃ It can condense most solvents, and for alcohol, 105℃ is recommended).

And another important reason to consider samples is that if acid is used, we must to consider how to prevent corrosion, especially for the vacuum pump. Solvents can damage rubber and plastic components and should also be protected. At this time we can choose the appropriate coating treatment of rotary evaporator

. -

-

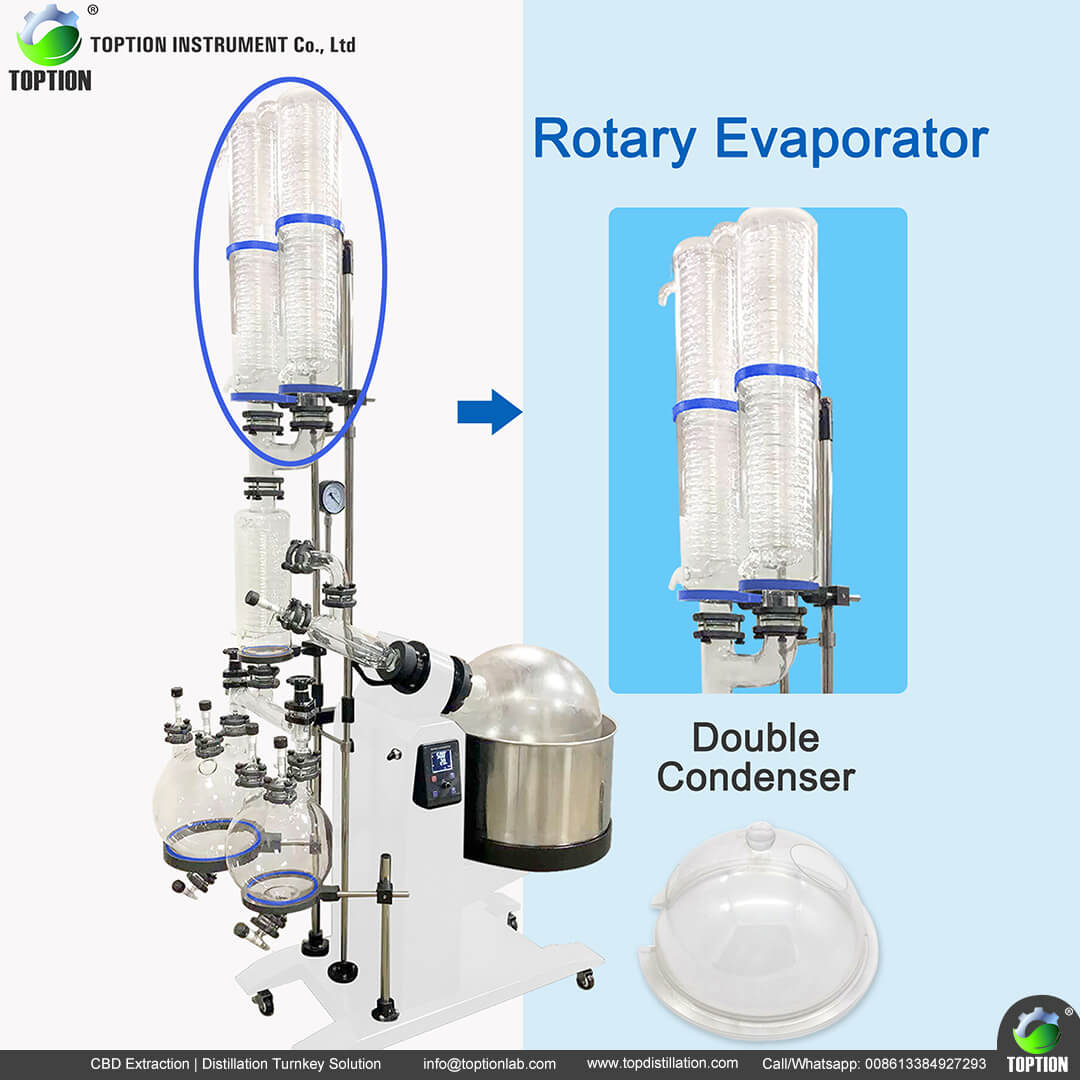

2. There are many options for condensers, which are directly related to the efficiency of sample collection. Large condensing area will of course improve collection efficiency and reduce waste. In addition, the condensing method you choose is also very important. Under normal circumstances, it can be used with tap water and dry ice, but if conditions permit, it is more efficient to use a chiller. This not only achieves efficient condensation, but also does not waste tap water or dry ice.

3. Safe operation, during the operation of rotary evaporator

, the bath is always heating. If oil bath is used, the temp. may be as high as 180℃. To prevent scalding from spilled liquid, a protective cover is very important for operators. For large-capacity rotary evaporators, the automatic lifting mode is preferred.4. The later maintenance should be simple, such as seals, pipes and glass joints, should choose suitable materials and excellent production process.

-

TOPTION as 15+ years manufacturer of rotary evaporator

, wish to help you choose the most suitable rotary evaporator, help you improve the efficiency of your research / production, reduce investment costs, and obtain the highest return on investment. Welcome contact: [email protected]

to get one-to-one professional consultation and assistance.