-

Chinese verified jacketed glass reactor vessel

top manufacturer, provide 500ml-250L fully customizable, with chiller,heater, vacuum pump complete set, to achieve concentration, distillation, reflux, separation, purification reaction purpose, widely used in chemistry, bio pharmaceutical, scientific research and experiment industries,etc. -

-

-

How to use jacketed glass reactor vessel?

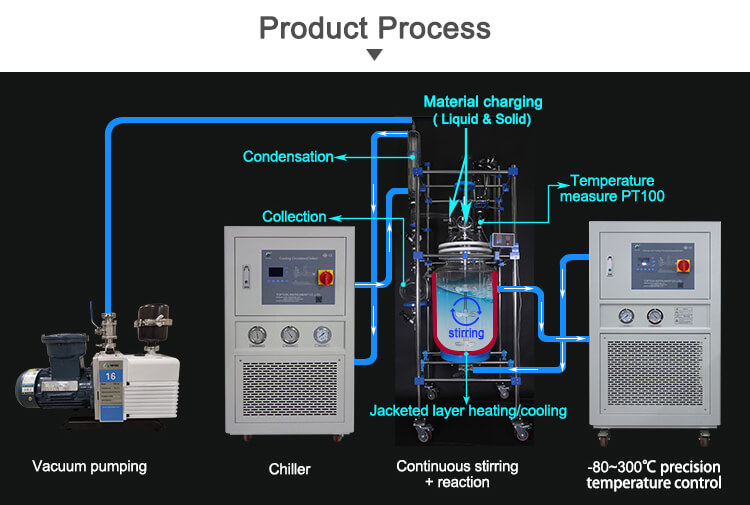

1. Charging your reaction material in the inner layer of the glass reaction vessel, turn on the stirring motor to perform the stirring reaction, and the speed can be adjusted by controller ( Standard type & Upgrade explosion proof controller are optional according to your material).

2. The glass reactor

jacketed layer is used for circulating heating or cooling reactions (refrigerated liquid, hot water or hot oil). By controlling the temperature of the heat and cold temperature source connected to the inter layer, it is generally matched with high and low temperature circulating bath for precise temperature control.3. Heating, cooling or constant temperature control of the materials inside the chemical glass reactor kettle.

-

-

4. Under the set constant temperature condition, in a closed glass reactor

, the stirring reaction can be carried out under normal pressure or negative pressure according to your requirements of use. Generally, a vacuum pump is connected to achieve the purpose of vacuum control.5. It can also do the reflux and distillation of the lab research reaction solution, and it can be vacuumed during use to do the vacuum reaction.

-

Want to find glass reactor factory, contact [email protected]

verified factory stocks available for sale, ISO CE SGS TUV BV certification, 15+ years experience, fully customizable supported.