Standard Layer 50L Jacketed Glass Reactor

-

Heater & chiller, vacuum pump, vacuum controller are available.

PLC automatic control system could be customize.

- Description

Description

Description

-

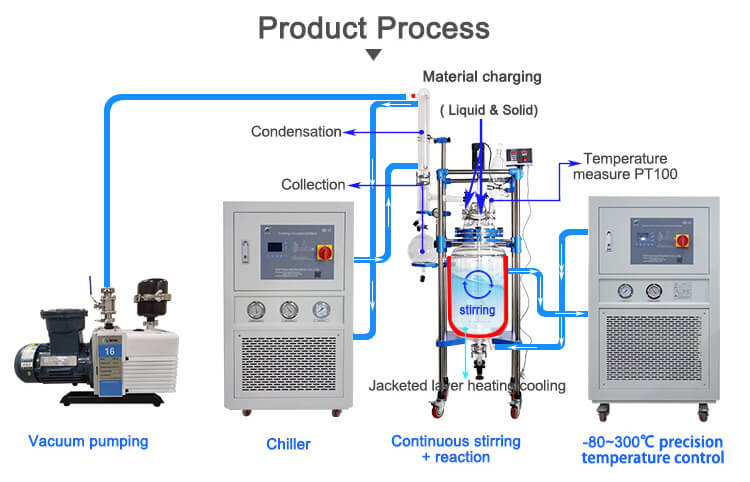

Product Introduction Of Standard Layer 50L Jacketed Glass Reactor

The double-layer glass reactor is a double-layer glass design. The inner layer of the double-layer glass reactor / double-layer glass reactor is placed in the reaction solvent to make the stirring reaction.

-

Technology Parameters Of Standard Layer 50L Jacketed Glass Reactor

Technology parameters

TOPT-5L

TOPT-10L

TOPT-30L

Stir medium flange

40

50

50

Liquid material inflow

24# 1L

34# 1L

34# 1L

Condenser

24#

34#

34#

Temp. measure

19#

DN15

DN15

Multi function valve

24#

DN25

DN25

Solid charging port

—–

DN80

DN80

Stirring paddle

ï¿ 10mm single layer two blade paddle type

ï¿ 16mm single layer three blade paddle type

ï¿ 16mm single layer three blade paddle type

Reactor lid flange (mm)

180

265

265

Inner diameter of reactor body(mm)

180

230

290

External diameter (mm)

230

290

330

Reactor body height(mm)

400

450

550

Power (w)

60

120

120

Rotate speed (rpm)

50-600

50-600

50-600

-

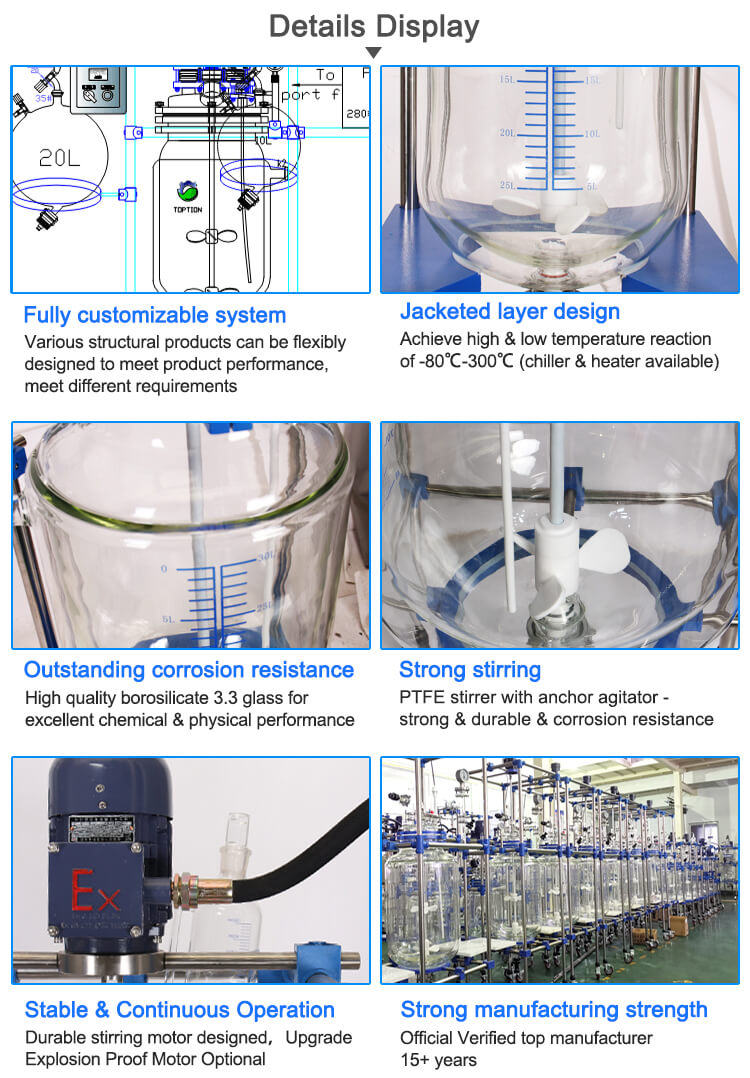

Product Feactures Of Standard Layer 50L Jacketed Glass Reactor

1.High quality High borosilicate glass 3.3.Our glass material is with even thickness and there is no foam in it.2.Stirring seal plug adopts â€mechanical seal, dynamic ring and the static ring buckle Principleâ€.3.Our motor is with stable function.4.Our speed regulator is with frequency adjustment.5.We use stainless steel screws for all screws, and galvanized screws for other factories.6.The whole support frame is with stainless steel (thickness less than 1.5mm).7.Stirrer is with full coated PTFE. Most other suppliers is half coated PTFE to save cost.8.All our seal material is high quality PTFE.9.Bottom discharge is with perfect design and high quality material to ensure no liquid leakage. -

ISO | CE Certification reliable quality jacketed glass reactor manufacturer with more than 15 years