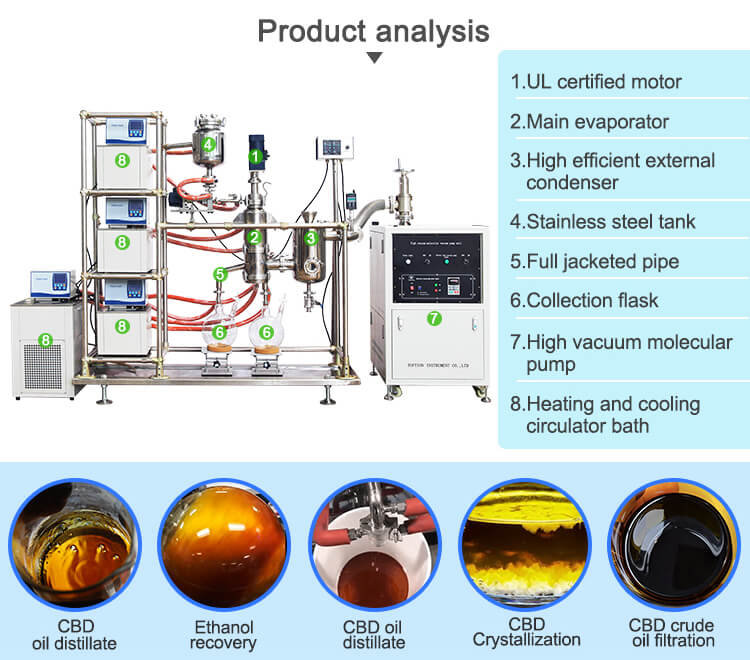

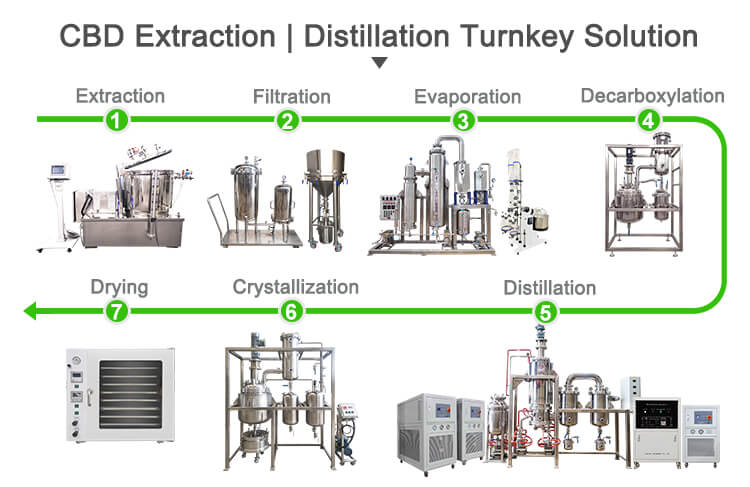

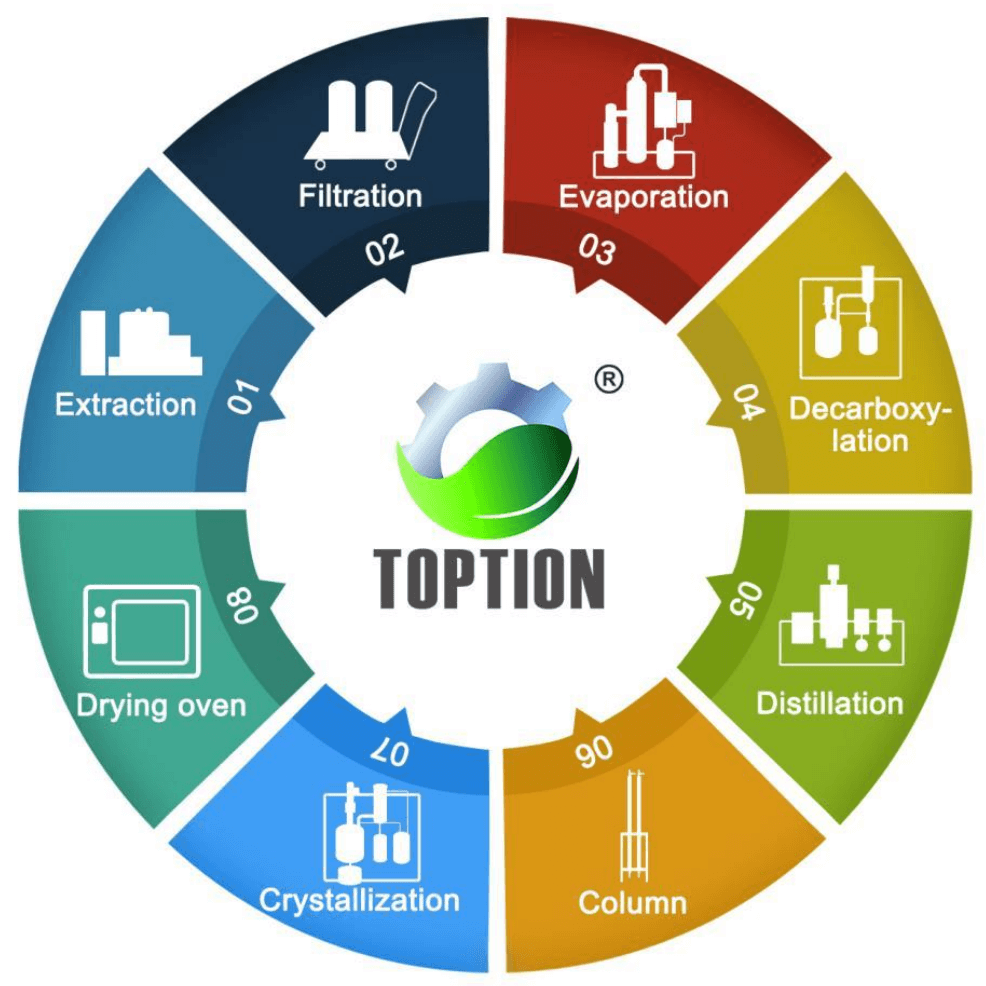

Short Path (Molecular) Distillation System

-

A comparatively new separation technology.

Suitable to separate substance of high boiling point, heat sensitive and easy to be oxidized.

Separation process in trades like Food,Pharmaceutical, Fine chemical, Electronic materials, Polymers,etc.

- Description

Description

Description

-

Short Path (Molecular) Distillation System

Molecular Distillation / Short Path Distillation is a comparatively new separation technology, which is especially suitable to separate substance of high boiling point, heat sensitive and easy to be oxidized. It is widely used in cbd oil, fish oil, and pharmaceutical industries.Here we introduce an experimental short path molecular distillation, suitable for small research and production. The matching chillers & heaters and vacuum pump are matched together, which can save your cost and time,improve the efficiency of the entire vacuum distillation equipment. Of course, if you already have temperature control equipment and vacuum pumps, you can contact us, our engineers team ( with more than 15 years rich experience) will match the short path distillation equipment according to your actual needs.

-

Technical parameters of cbd oil molecular distillation equipment

Main body

Model

MDS-6B short path molecular distillation system

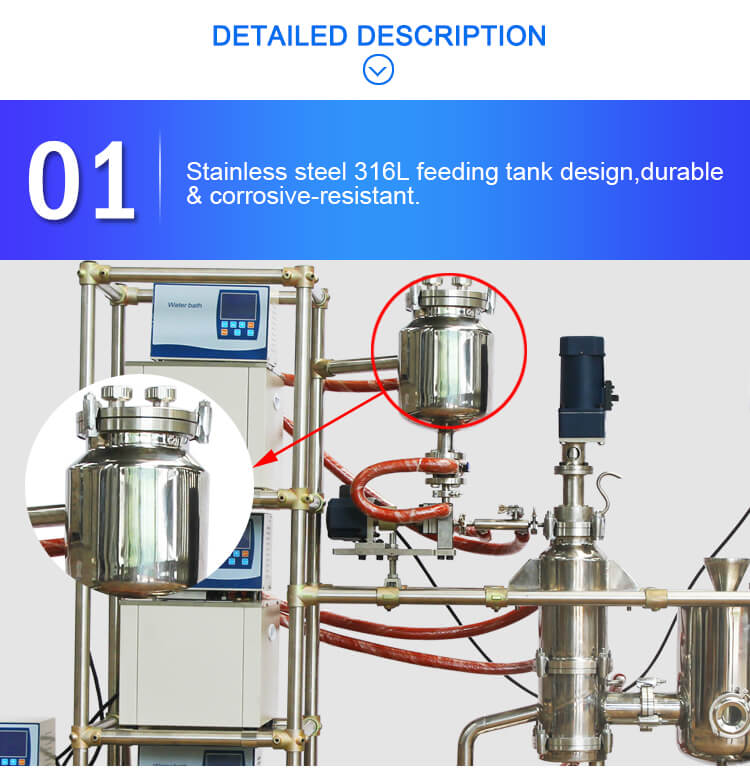

Material tank

3L jacketed stainless steel tank

2 sight glass at top, with insulated ball valve

Material charging

Gear pump

Flow 0.5L~3L/H

120W motor, electronic speed regulation.

Evaporator

Evaporation area 0.06㎡

Film forming way: scraper (roller is optional)

Material:316L

Mechanical seal (Magnetic seal is optional)

Film forming motor:200W motor, electronic speed regulation.

Cold trap

1. 0.2㎡chiller cooling cold trap

2. 1L liquid nitrogen cold trap

3. Dual-purpose (chiller & liquid nitrogen cold trap dual purpose).

Choose 1 in above 3 types

Heavier component discharge

29# Grinding mouth adapter

5L glass bottle 1pcs, bottle holder 1pcs

Lifting table 1pcs

Lighter component discharge

29# Grinding mouth adapter

5L glass bottle 1pcs, bottle holder 1pcs

Lifting table 1 pcs

Material pipeline

Jacketed insulation

Shelf & assemble

304 stainless steel pipe

Accessory

Vacuum

1. No-load < 10PA

2. No-load < 5PA

3. No-load < 0.01PA rotary vane molecular pump set (Single phase 220V)

Vacuum gauge

Resistance / thermocouple vacuum transmitter

Main evaporator heating

300℃/3KW

Raw material section insulation

200℃/1.5KW

Heavier component

insulation

200℃/1.5KW

Lighter component condensation & insulation

(CBD lighter component could share with material feeding tank)

Internal condenser — High & low temperature all-in-one machine GD-10200-5

Insulation —200℃/1.5KW

External cold trap cooling

1. Liquid nitrogen cold trap.

Or 2. Chiller

-

The advantages of short path molecular distillation equipment

- 1. Material be heated in short time

Rotating scraper push the material on the heating surface and the material liquid spiraling continuously moves down and escape from the heating surface, the material which is separated escape from the heating surface was quickly collected by condenser cooling, this method has to minimize the contact time of material and heating surface.

Successfully eliminates the thermal decomposition, polymerization, or metamorphic.

- 2. Low evaporation temperature

Short path distillation apparatus through material liquid distributor and rotating scraper to make material be uniform distribution on the heating surface, reducing the pressure difference which is generated on material static liquid surface.

3. Self-cleaning heating surface

- Short path distillation system can successfully be applied to the material concentration and separation which is easily bubble, in the heating surface fouling in conventional distillation.

- 4. High efficiency evaporation, strong adaptability, easy operation

Rotating scraper makes the material be uniform distributed on heating surface as a film, the liquid film always maintain high turbulence state, which accelerates the heat transfer to reduce the heat loss.

Simple structure, convenient cleaning, freedom of start-up and shut-down, suitable for many varieties, discontinuous small chemical production.

-

ISO approved, CE certification reliable quality molecular distillation equipment manufacturing, UL certified configurations are available, professional customize & free consult welcome contact [email protected]