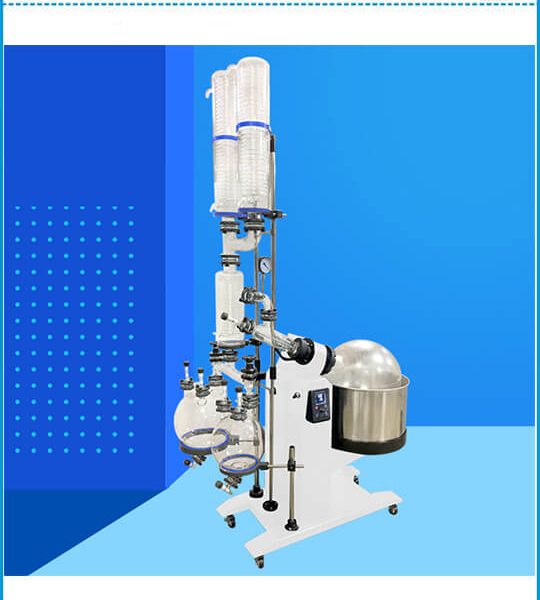

50L Alcohol Distillation Rotary Evaporator

-

1.Idea instrument for concentration, drying and recycling.

2.Explosion proof of motor, controller and bath.

3.220V, 50/60Hz, 110V support customize.

- Description

Description

Description

-

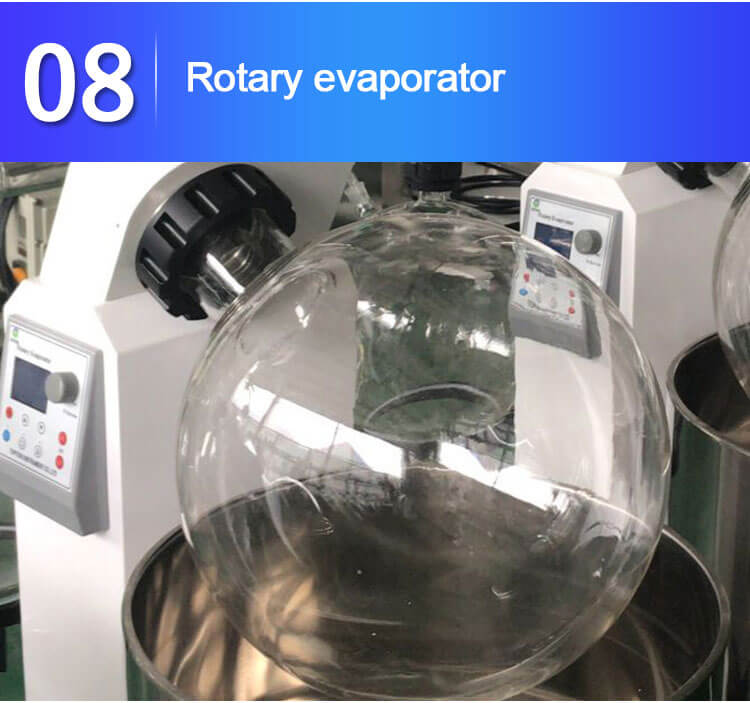

50L Alcohol Distillation Rotary Evaporator Large screen LCD display rotary evaporator

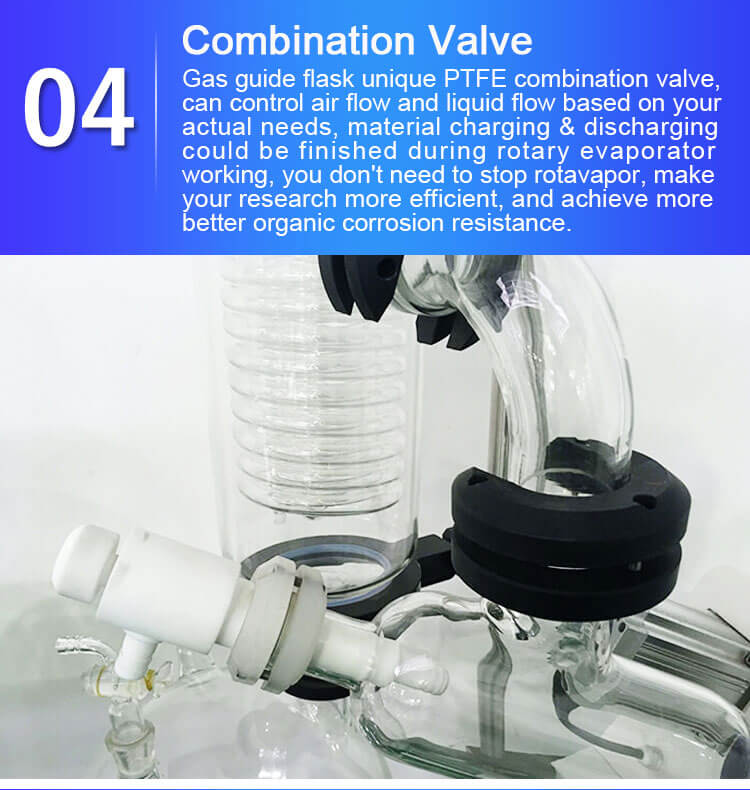

, 2022 new design with built-in automatic check valve, for better vacuum degree and good continuously operation. Material charging & discharging could be finished during rotary evaporator working, you don’t need to stop rotavapor when you need to charging or discharging the material, make your research more efficient, and achieve more better organic corrosion resistance. -

Wide capacity range customization from 1L 2L 3L 5L laboratory small scale, 10L 20L 30L 50L pilot sale, and 100L industry model with Hydraulic lifting device, for rotary evaporators

with a capacity of 10L or larger models, TOPTION provide customization of explosion-proof systems, customization of dual condensers to obtain larger condensation area, so as to improve condensation efficiency, and customization of collection bottles with lower discharge valves. -

As the manufacturer of rotary evaporator with more than 16 years experience, provide technical support, professional customization service, OEM, factory directly sale with most competitive price, and TOPTION have through ISO CE SGS TUV BV certification, dependable quality guarantee.

-

Technical parameters of 50L rotary evaporator

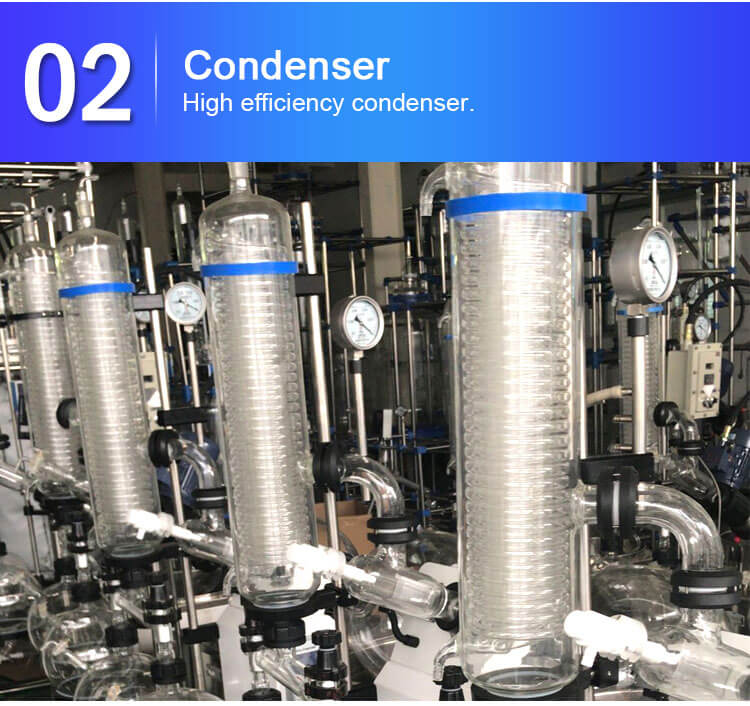

Rotary evaporator model RE-5250A 50L evaporator Evaporation flask 50L / F125 Receiving flask 20L + 10L with bottom discharge, for continuously working Condensers Condensing surface is 1.5 m2 Rotation speed 3-110 rpm Lifting type Automatic lifting for easy operation Power 220V, 50/60Hz Complete set Available, with chillers, vacuum pump, vacuum controllers -

Structure of rotary evaporator new design

-

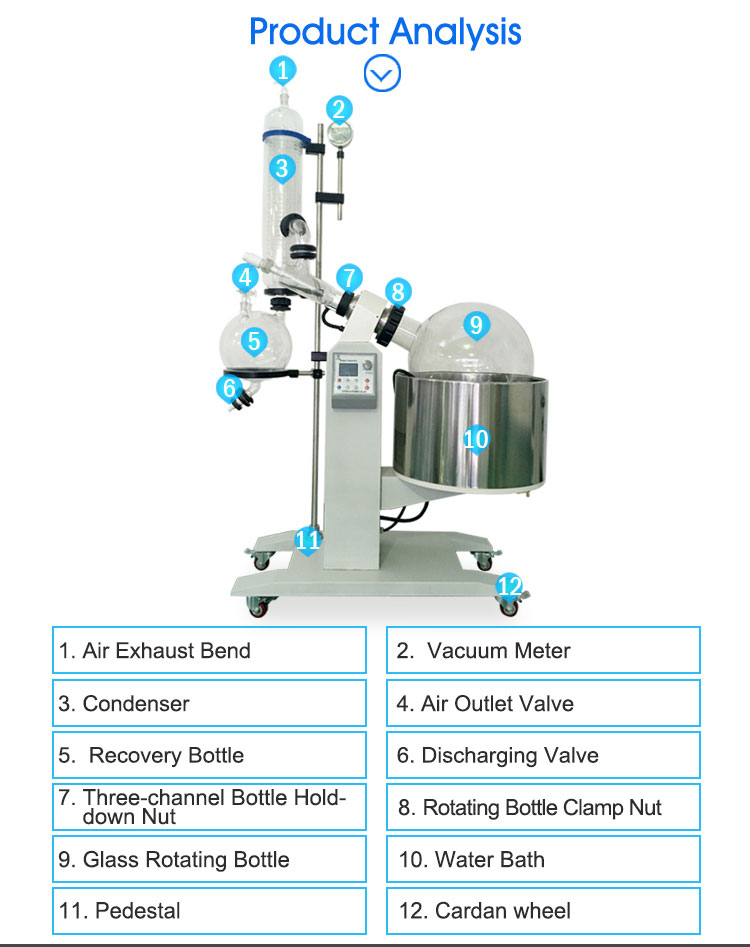

1. Three-channel Bottle

2. Three-channel Bottle Hold-down Nut

3. Three-channel Bottle Hold-down Nut Retaining Ring

4. Flange Sealing Retaining Ring

5. Glass Rotation Axis

6. O-ring

7. Coupler

8. Teflon Sealing Ring

9. Rotating Bottle Hold-down Nut Retaining Ring

10. Rotating Bottle Clamp Nut

11.Glass Rotating Bottle

12. Condenser Pipe Clamp

13. Cross Clamp

14. Top Upright Tube

15. Down Upright Tube

16. Pedestal

17. Vacuum Meter

18. Vacuum Meter Stand

19. Motor Box

20. Water Bath

21. Air Exhaust Bend

22. 60# Connecting Flange

23. 60# Flange Retaining Ring

24. 60# Flange Seal Washer

25. Main Glass Condenser Pipe

26. Assistant Glass Condenser Pipe

27.Assistant Glass Condenser Pipe Bracket

28.50# Connecting Flange

29. 50# Flange Retaining Ring

30. 50# Flange Seal Washer

31. Automatic Switch Valve

32.Air Outlet Valve

33. Recovery Bottle

34. Recovery Bottle Tray

35. Discharging Valve

36. Charging Valve

-

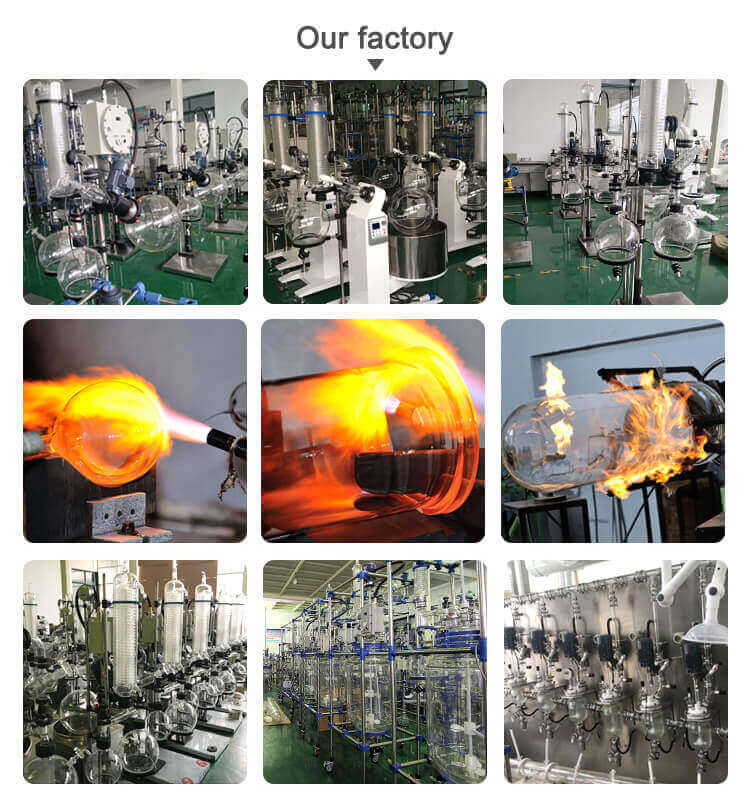

Rotary evaporator glass production process

-

Storage is available for fast delivery, wooden package for safe shipping

-

One stop solution of rotary evaporator whole set, include chiller, vacuum controller, vacuum pump, from 0.5L to 100L rotary evaporator customize.

-

Contact info@toptionreactor.com

to customize your rotary evaporator machine.