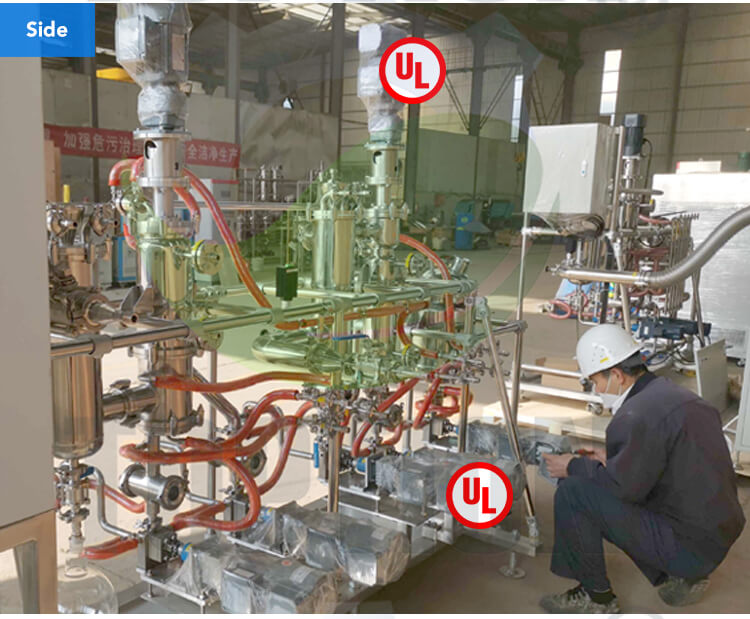

UL wiped film evaporator 2 stages

-

1. UL certified configurations. CE type is optional.

2. Wiped film evaporator + molecular distillation two stage design, help you save cost & improve efficiency.

3. Heater, chiller, vacuum pump complete set.

- Description

Description

Description

-

Brief introduction of wiped film evaporator:

TOPTION this 2 stages type wiped film evaporator is professional customization type, first stage is wiped film evaporator, which is used for ethanol recovery / solvent remove, second stage is 5 inch molecular distillation to separate pure cbd oil, with UL certification configurations.

-

Laboratory evaporator technical parameters ( more models and other customization requirements please contact)

-

Material

Stainless steel jacketed design First stage 2-10L/h wiped film evaporator

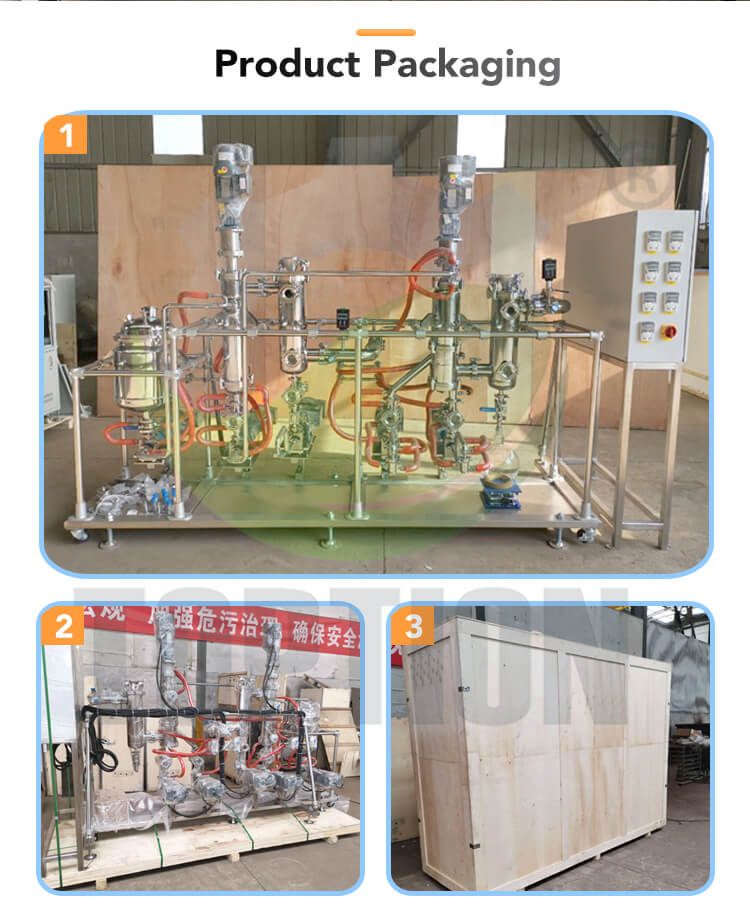

Second stage 5 inch stainless steel molecular distillation unit Material charging and dischargrng UL certified gear pump Vacuum system 10Pa, 1Pa, 0.05Pa (UL certified pumps optional) Heating and cooling system Heater and chillers are avilable Package Professional exported wooden box package Certification UL certified. -

TOPTION commitment to wiped film evaporators:

From lab scale small distillation equipment, pilot type to industrial production, TOPTION all support one-to-one customized services. If you don’t have a clear idea about distillers product selection, please tell us your needs by info@toptionreactor.com

. TOPTION have a professional team of engineers and business team assists in analyzing your cbd processing equipment requirements and designing the most practical solution, and the whole process supports video communication, smooth and timely.