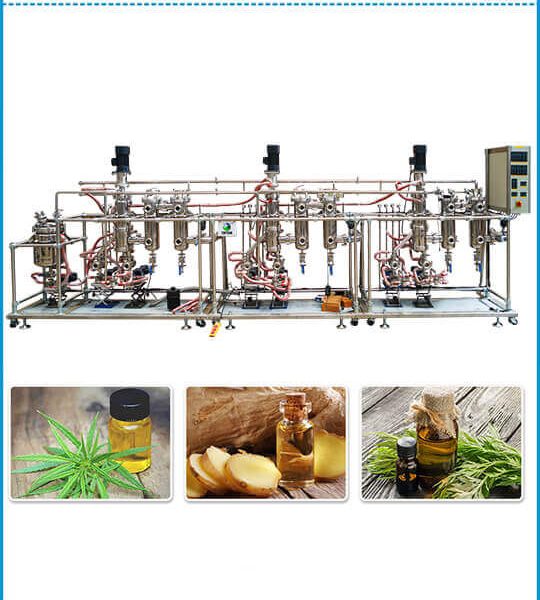

Short Path Wiped Film Evaporator

-

1. 10L jacketed glass material feeding tank.

2. S304 stainless steel evaporator surface: 0.1㎡.

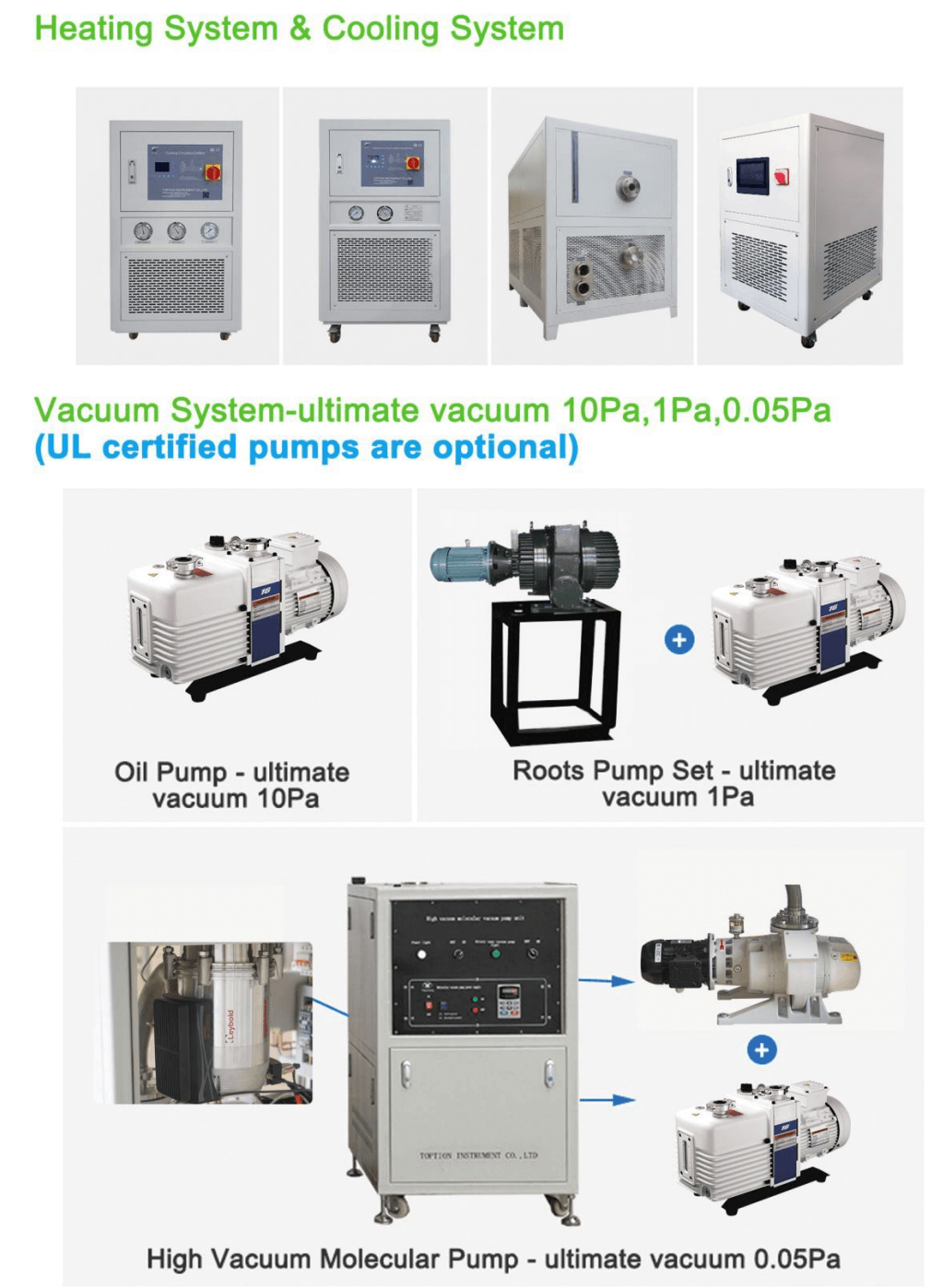

3. Heating & cooling system, vacuum system equipped well.

- Description

Description

Description

-

A complete short path wiped film evaporator apparatus set should include:

1. Short path evaporator. 2. Heating system. 3. Material charging system. 4. Cooling system. 5. Vacuum system. 6. Material collection unit, etc. -

Technical parameters of short path wiped film evaporator:

Model

MDS-30C molecular distillation equipment

Material tank

30L jacketed tank

2 sight glass at top, with insulated ball valve.

Material charging

Gear pump

Flow 5L~30L/H

200W motor, electronic speed regulation.

Evaporator

Evaporation area 0.2㎡

Film forming way:scraper (roller is optional)

Material:316L

Mechanical seal (Magnetic seal is optional)

Film forming motor,370W, mechanical constantly variable transmission,200~1000rpm/min

Cold trap

1. 1㎡chiller cooling cold trap

2. 3L liquid nitrogen cold trap

Dual-purpose(chiller & liquid nitrogen cold trap dual purpose)

Choose 1 in above 3 types

Heavier component discharge

Gear pump

Flow 5L~15L/H

200W motor, electronic speed regulation.

Lighter component discharge

Gear pump

Flow 5L~30L/H

200W motor, electronic speed regulation.

Material pipeline

Jacketed insulation

Shelf & assemble

304 stainless steel pipe

Main features of TOPTION MDS-10C short path molecular distillation apparatus:

1. Material feeding tank: 10L jacketed glass tank. High precision gear pump feeding (3-15L/H).

2. Short path evaporator’s material (contact with products): S304 stainless steel. Evaporator surface: 0.1㎡

3. Heavier component discharge system & Lighter component discharge system both are 29# Internal grinding

mouth glass collection bottle and vent valve collection material: 5L.4.Heating & Cooling Unit are equipped well.

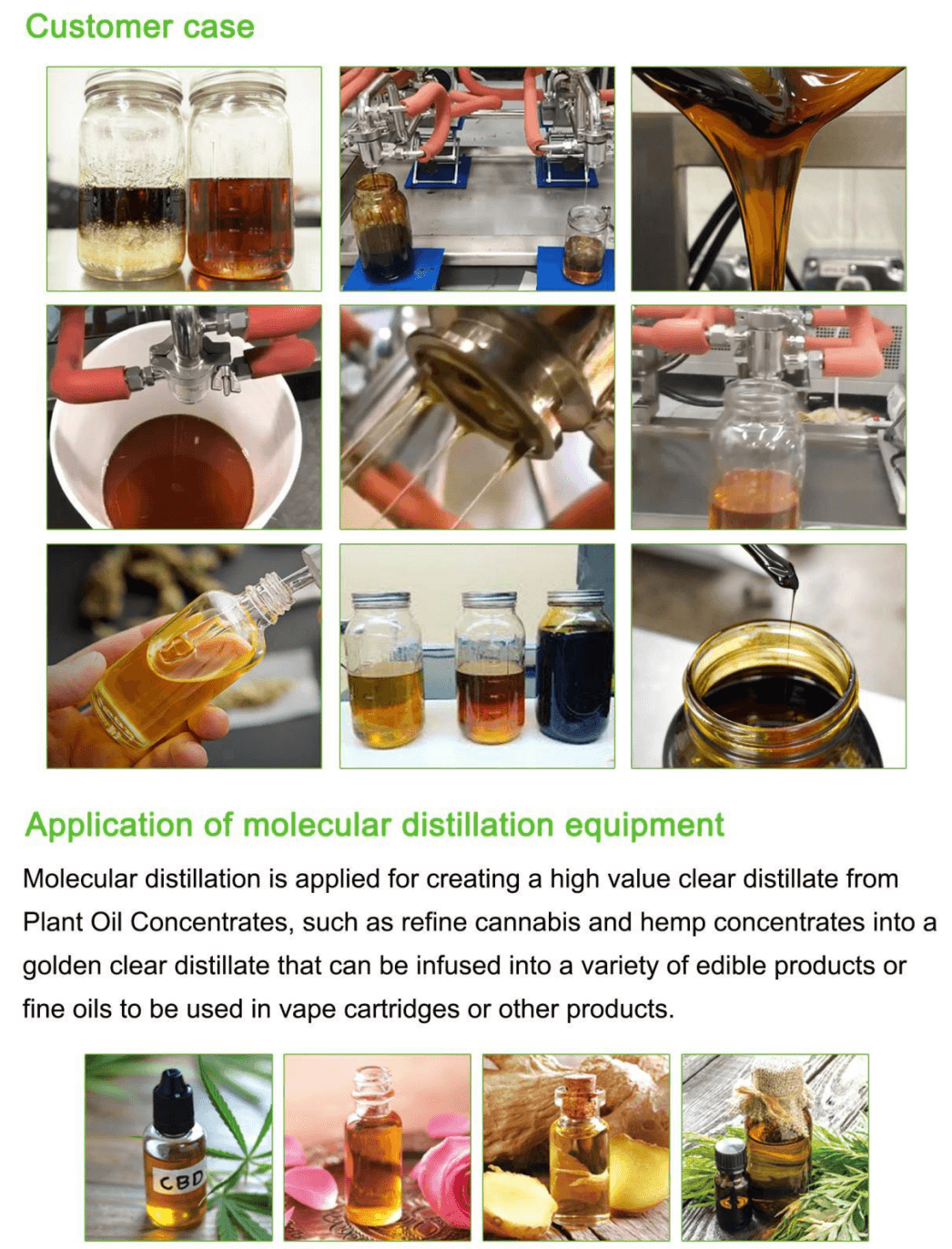

5. Vacuum system:

-5.1 Vacuum degree 10pa, need to equipped with TRP-36 vacuum pump: 9L/S.

-5.2 Vacuum degree 1pa, need equipped with TPR-36 vacuum pump + roots pump unit ZJP-150S.

-5.3 Vacuum degree 0.1pa, need to equipped with oil pump + oil diffusion pump unit T150.6. CE | UL certification, ISO approved, reliable quality manufacturing 15 years.

-

TOPTION provide short path wiped film evaporator overseas installation / training service, also welcome factory visit contact info@toptionreactor.com

24h/7days online service.