Chemical vacuum distillers

-

1.Chemical vacuum distillers can be implemented in a variety of customized modes.

-

2.Multi-stage chemical vacuum distillers optimize the purification effect.

-

3.Double stainless steel feeding tank and gear pump working time 24 hours a day for 7 days can enhance the experimental efficiency.

- Description

Description

Chemical vacuum distillers

-

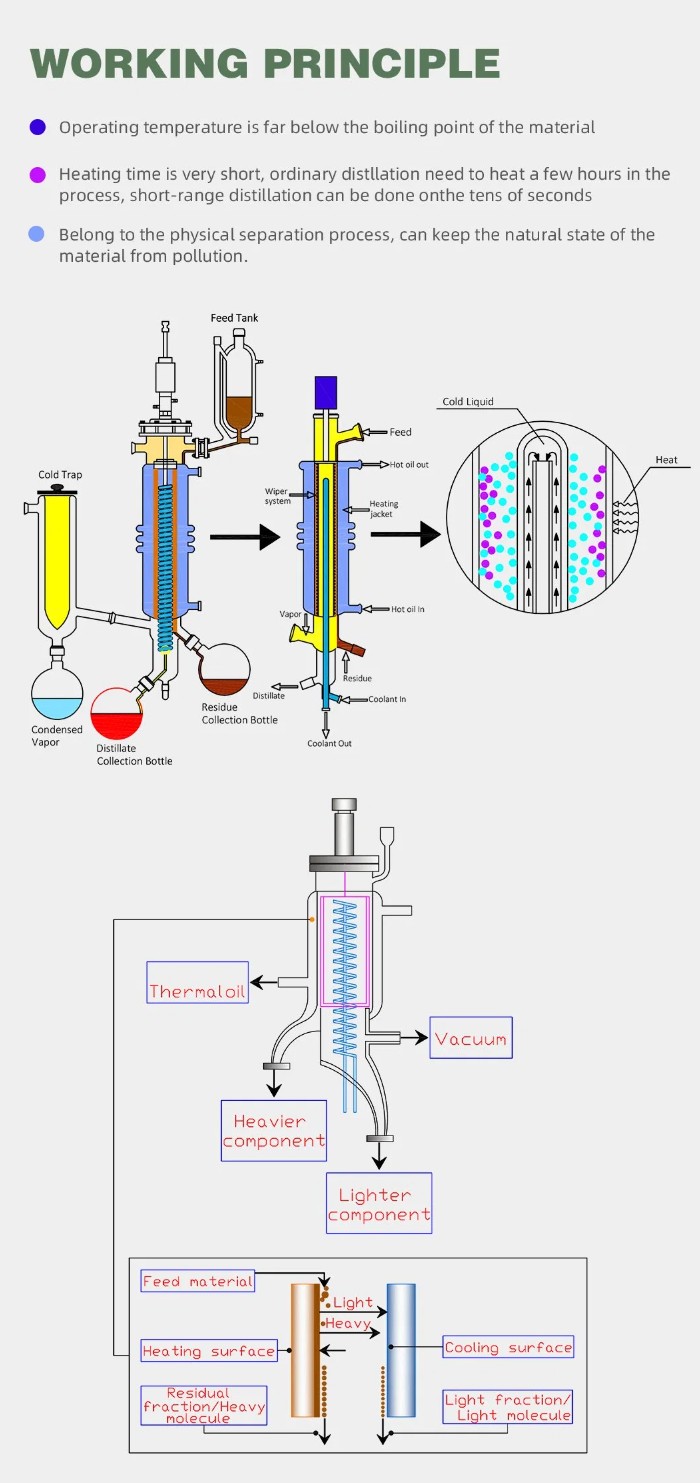

The three-stage chemical vacuum distillers can be applied in the field of oil purification and lubricant reuse. Using the different evaporation temperatures of impurities and target products, the chemical vacuum distillers separate the two at a lower temperature, which can effectively remove other substances in the liquid, such as organic solvents, odors, etc.

-

Chemical vacuum distillers a pure separation apparatus, used in conjunction with other extraction equipment and requires high pre-treatment of materials. In the chemical industry, molecular distillation equipment is used in waste lubricant regeneration operations, where the waste lubricant is pretreated and light components are removed. The waste lubricant is distilled in a distillation tower after spare diesel fuel is removed as raw material until a better base oil is regenerated.

-

-

We provide you with different parameters for different models. According to the nature of the separated materials, the reasonable selection and configuration of each unit is very critical to the performance of the complete distillation unit, and Toption expertise and technology strongly support the chemical machinery manufacturing technology, and the complete configuration is more relevant and relevant to the customer’s requirements. Welcome to consult info@toptionreactor.com for the price list and service list.

-

-