Dewaxing filter lab filtration equipment

-

1. 50L hotsale, up to 250L and larger type customization is supported.

2. Dewaxing, Winterization, Filtration.

- Description

Description

Description

-

1.How much time will I save by using TOPTION dewaxing filter lab filtration equipment?

Typically dewaxing filter the use of small Buchner flasks for dewaxing a winterized solution becomes a bottleneck in production. This bottleneck costs you labor & time. Although we can’t give an exact time for TOPTION filtration, for a typical winterized solution, you should expect to filter 4 L in less than a half hour. Laboratory filter for lightly waxed winterized solutions, you should expect 4L in less than five minutes. The general rule is, the heavier the wax content, the longer the filtration time.

2.How do I clean the vacuum laboratory filter?

You can clean dewaxing filter by removing the top from the base. The stainless steel is entirely food grade finish so that you will not risk cross contamination. We recommend the use of ethanol to clean the surfaces.

-

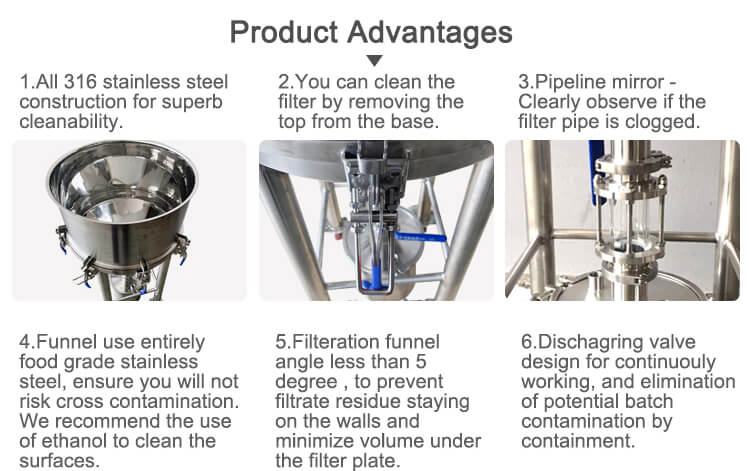

The advantages of TOPTION wax removal filtration equipment ( remove waxes from your oil in snap)

1. Whole set laboratory filter

equipment use 316L stainless steel construction for super cleanability.2. You can clean the filter by removing the top from the base. Very convenient and easy operation.

3. Pipeline mirror – clearly observe if the filter pipe is clogged.

4. Funnel use entirely food grade stainless steel, ensue you will not risk cross contamination. We recommend the use of ethanol to clean the surfaces.

5. Filtration funnel angle less than 5 degree, to prevent filtrate residue staying on the walls and minimize volume under the filter plate.

6. Discharging valve design for continuously working, and elimination of potential batch contamination by containment.

7. Incorporation of containment vessel for improved isolation from the environment. And the filtrate will be collected in the containment vessel.

8. 3, 5, 10, 20 micron sizes filter paper / filter bag, vacuum pump are available.

9. Stainless steel filter plate – strong & long-term stable pressure bearing capacity, to ensure long service life of filter.