Fractional Column

-

1. Wide selection of product capacity, 1 L-20 L,50 L.2. Flexible product characteristics to accommodate concentrations of nitric acid and other heat-sensitive media.3. Certifications: ISO, CE, SGS, TUV, UL, etc.4. Applications: Pharmaceuticals, intermediates, fine chemicals, dyestuffs, paints and varnishes, etc.↓ Boost workflow. Consult TOPTION ↓

- Description

Description

Fractionating Column

-

TOPTION Fractional Column Specialist

-

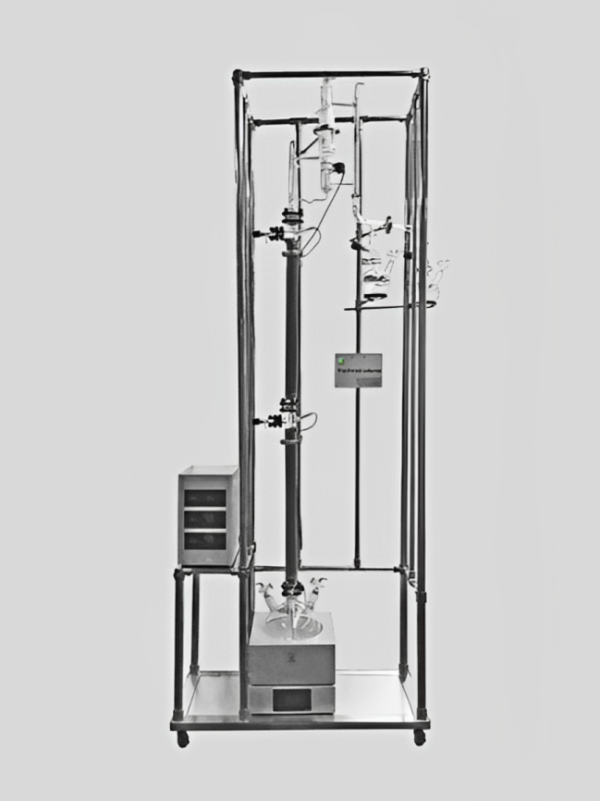

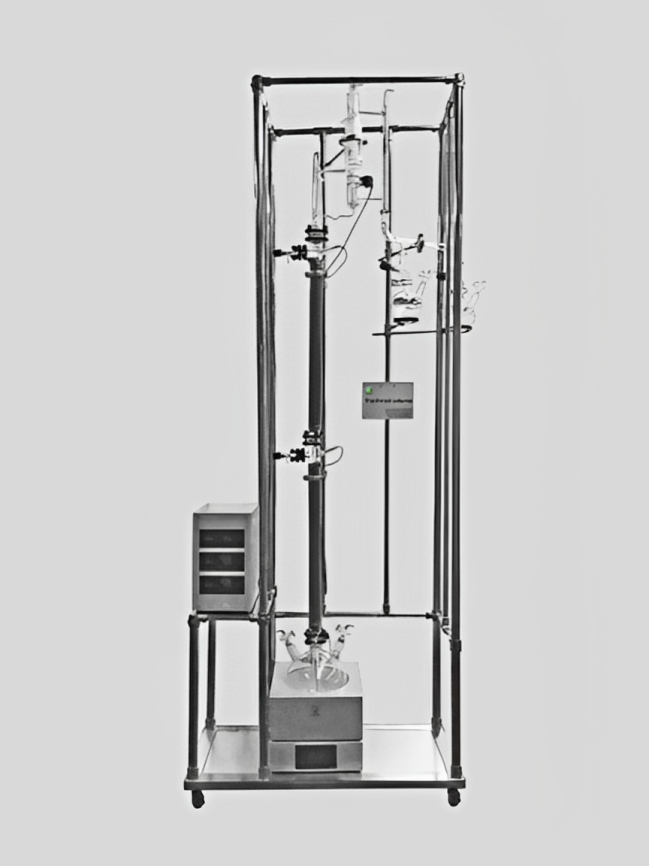

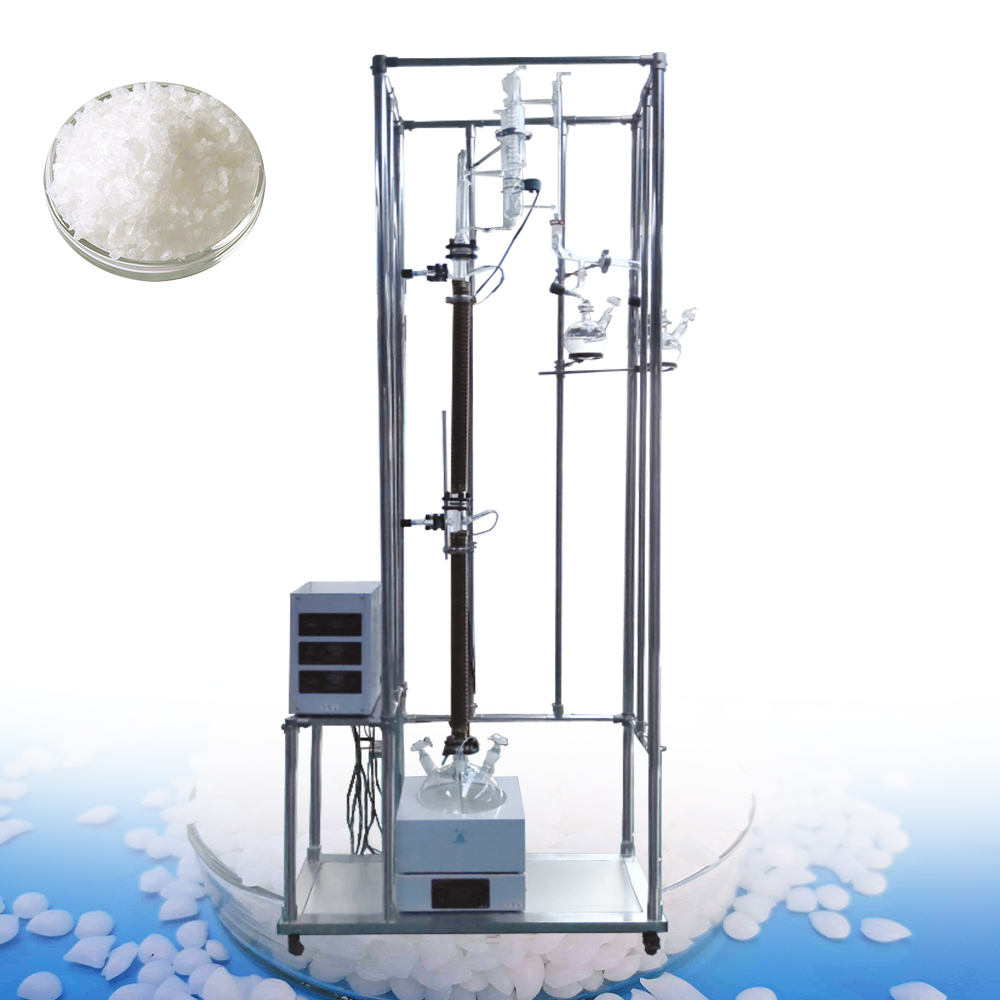

TOPTION is proud to introduce fractionated columns, a cutting-edge solution for separation and purification processes. Designed with advanced technology, Fractionated Columns are efficiently engineered to provide unrivaled performance for a wide range of industries. In this comprehensive product overview, we explore the benefits, principles, features, and applications of TOPTION Fractionated Columns, demonstrating their ability to take your separation and purification processes to new heights.

-

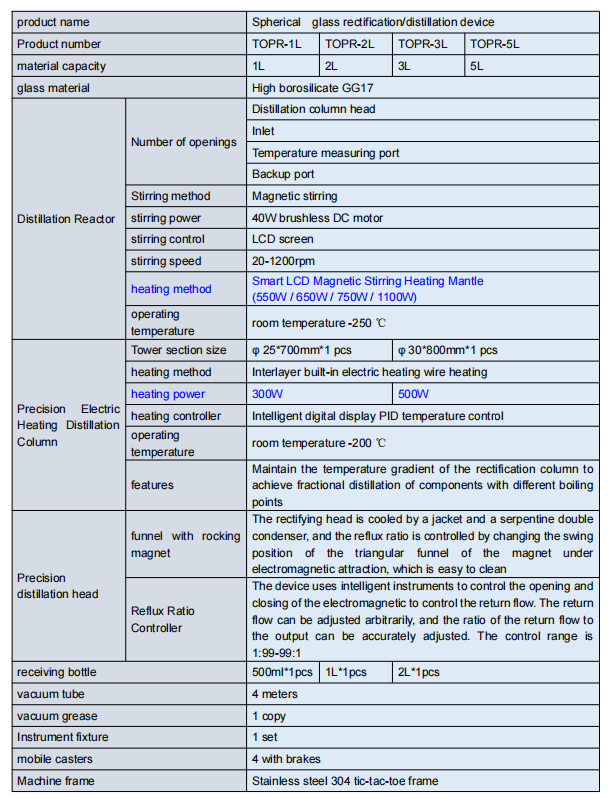

Products Parameters

-

-

Products Features

-

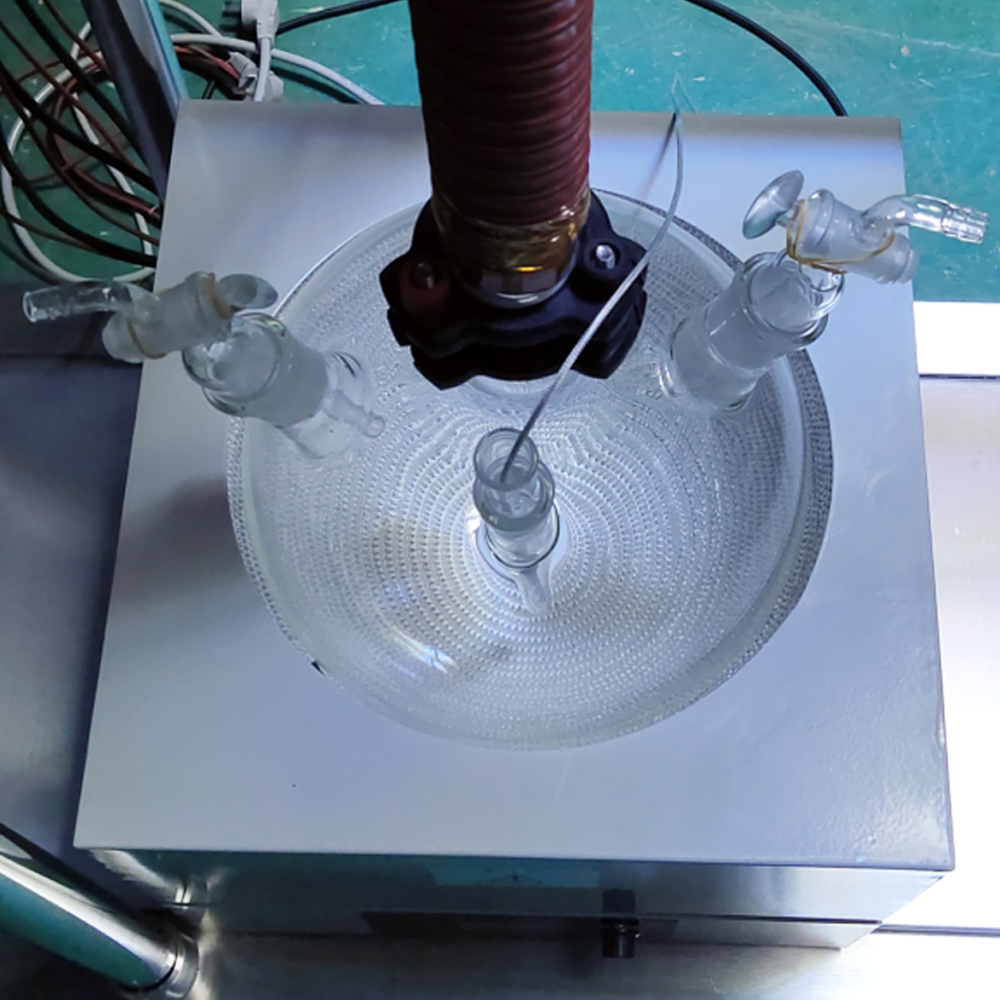

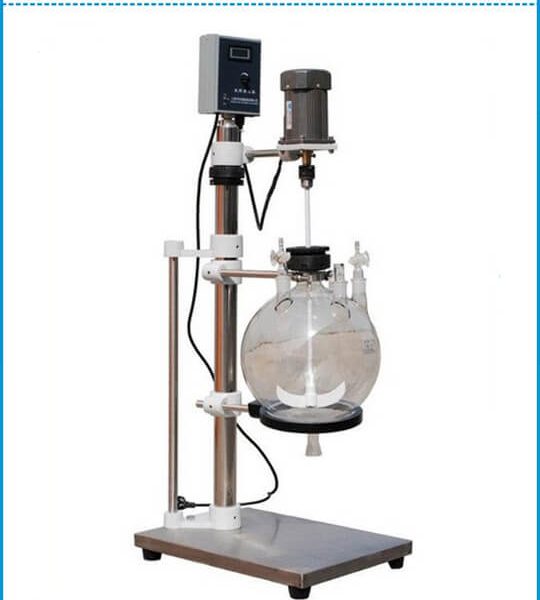

Fractionating Column is widely used in separation, purification, and distillation processes in various industries. Spherical Glass Reactor refers to a type of equipment that is mainly used for reactions and other processes in the chemical and pharmaceutical industries. This equipment is specialized in maintaining different processes under controlled conditions.

The reactors are made of glass and offer excellent resistance to a wide range of chemicals, ensuring that they are durable. The spherical shape also provides an efficient heat transfer system, making it more suitable for controlling temperatures in a variety of processes.

Reactors typically include several components such as a stirring system, a heating or cooling system, a temperature controller, a condenser, and a collection tank. The transparency of the glass allows scientists and engineers to visually monitor the reactions and processes taking place within the reactor.

-

Working Principle

-

The fractionating column operates on the principle of fractional distillation, a process that separates different components of a liquid mixture based on their boiling points. The unit consists of a spherical glass vessel equipped with heating and cooling systems. The liquid mixture is heated to its boiling point, and the vapors rise through the vessel. As the vapors ascend, they condense on the cooler surface of the spherical glass, gradually separating into different components. The separated components are then collected through individual outlets.

-

Advantages

-

1. Excellent Heat Transfer: The spherical design of the glass vessel provides a larger surface area for heat transfer, ensuring efficient and uniform heating throughout the distillation process. This leads to better separation and higher product yields.

2. Corrosion Resistance: Glass is highly resistant to corrosion by most chemicals, making it suitable for distilling a wide range of substances, including corrosive liquids. This resistance ensures the purity and quality of the separated components.

3. Easy Monitoring: The transparency of the glass vessel allows for easy visual monitoring of the distillation process, ensuring optimal control and preventing any undesirable reactions or overruns.

4. Versatility: Spherical glass distillation units can handle a broad range of liquid mixtures and components, making them suitable for various industries and applications. They can be used for laboratory-scale processes as well as industrial-scale production.

5. Scalability: The design of spherical glass distillation units allows for easy scaling up or down, depending on the required production capacity. This scalability makes them adaptable to different processing needs and budgets.

-

Applications

-

1. Chemical Industry: Fractionating columns are extensively used in the chemical industry for the separation and purification of different chemicals, solvents, and intermediates, ensuring high purity and quality.

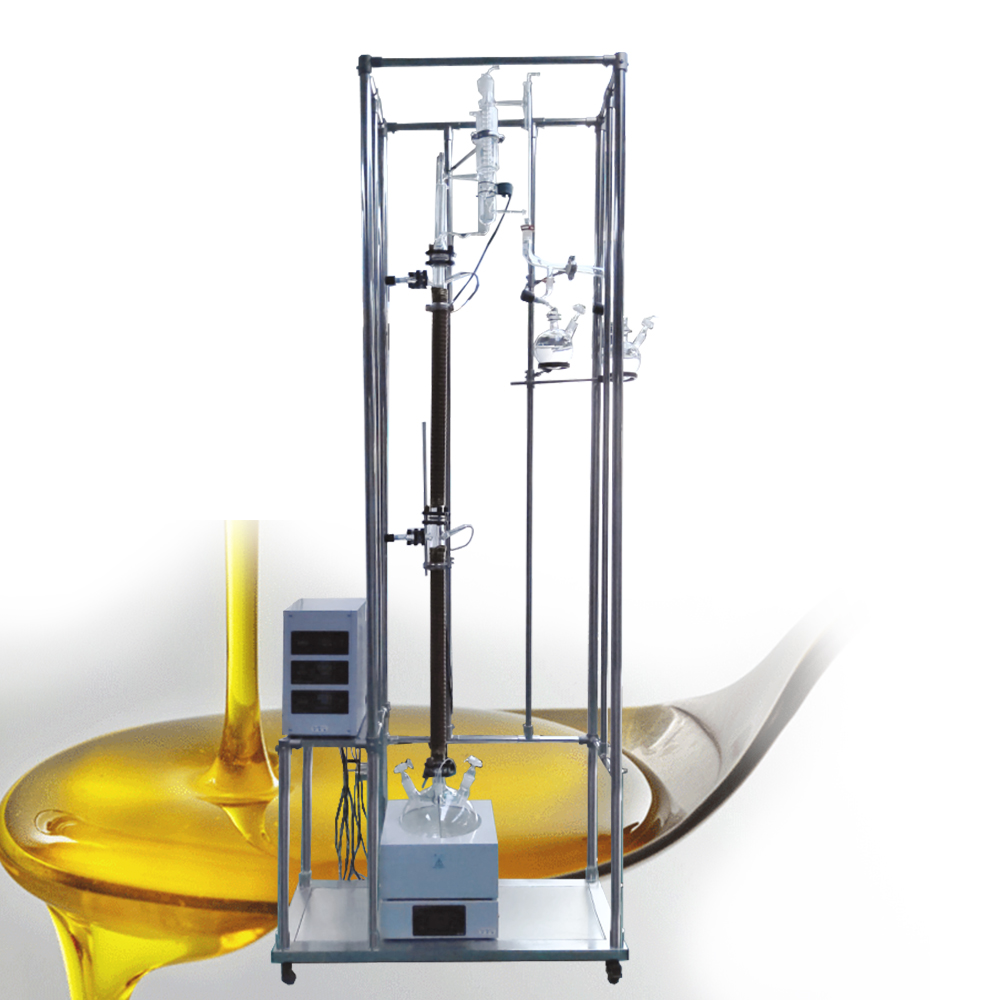

2. Essential Oil Extraction: These units are widely employed in the extraction of essential oils from herbs, flowers, and plants. The gentle distillation process preserves delicate aromatic compounds, resulting in high-quality essential oils for use in perfumes, aromatherapy, and other applications.

3. Pharmaceutical Industry: Spherical glass distillation units play a crucial role in the pharmaceutical industry for the purification and isolation of active pharmaceutical ingredients (APIs) and other compounds, ensuring pharmaceutical-grade purity and quality.

4. Food and Beverage Industry: These units are used for the distillation and purification of alcoholic beverages, such as whiskey, vodka, and rum. They help remove impurities, adjust flavors, and enhance the quality of the final products.

5. Research and Development: Spherical glass distillation units are extensively utilized in laboratories for research, experimentation, and process optimization. Their transparent design allows researchers to visually analyze the distillation process and adjust accordingly.

-

In short, fractionating column offer efficient and versatile solutions for separation, purification, and distillation processes in various industries. The working principle of spherical glass distillation units and their excellent heat transfer, corrosion resistance, ease of monitoring, versatility, and expandability make them ideally suited for chemical, pharmaceutical, food and beverage, and research applications. They are essential tools for achieving high-purity and quality products. Feel free to contact us at info@toptionreactor.com

. -

-