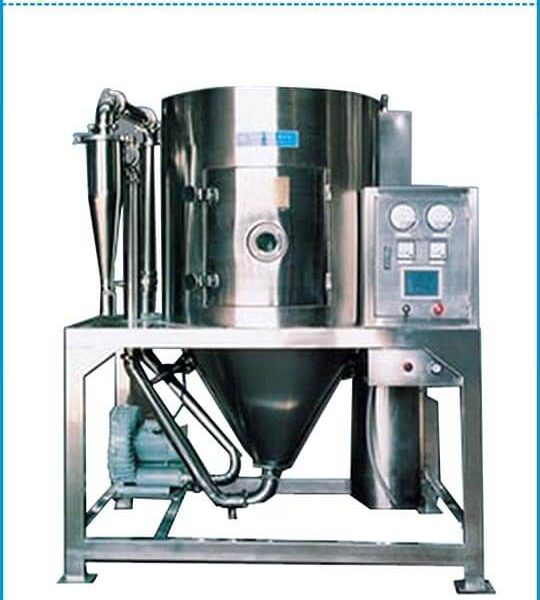

High Speed Centrifuge Spray Dryer Sodium Silicate Spray Drying

-

1. Online & On-site training and installation service are available.

2. ISO CE certification, 15+ years manufacture.

- Description

Description

Description

-

High Speed Centrifuge Spray Dryer Sodium Silicate Spray Drying process:

1.Outdoor air through effectively filter enter into heater, heating until its temperature reach the request of inlet gas temperature, through hot air pipeline reach to the hot air distributor which is at the top of drying tower, under the function of hot air distributor, air come into drying tower uniformly.

Material liquid (already after treatment) through screw pump sucked into high speed centrifugal atomizer which is at the top of drying tower. According to spray drying particle request, adjust the rotating speed of atomizer, let material liquid atomize into fog droplets, and contact with hot air, then from top to bottom drying into ideal products in drying tower.

Most products after drying through exhaust pipe which is at the bottom of drying tower to cyclone distrituber to collect the powder.

-

-

2.Material selection: spray dryer parts which are contact with hot air and material, stair railing and support are made of carbon steel; skeleton and frame are made of carbon steel.

3.Equipment processing: use argon welding, weld joint rub down smooth and polishing, no dead angle.

4.Drying tower straight cylinder install a door which has an observe hole, through this hole could observe the atomization situation on drying tower, open the door could clean and washing drying tower.

5.Electric control: electric cabinet use carbon steel material which has good heat dissipation performance. Inlet air temp. automatic control, it could be adjust automatic after set the inlet gas temperature degree, exhaust air temperature should be controlled manual.

According to products situation, adjust the flow rate of material feed pump, and control exhaust gas temperature. On the electric cabinet has inlet air temperature and exhaust air temperature display, and all operation buttons which are used to control equipment.

-

Items

TGZ-500

TGZ-800

TGZ-1000

TGZ-2000

TGZ-3000

TGZ-4500

TGZ-6500

Inlet temp.(℃)

140-350 Automatic control syste

Outlet temp.(℃)

80-90

Spray type

High speed centrifugal atomizer ( mechanical drive or stepless frequency control speed are optional )

Water evaporation capacity(kg/h)

500

800

1000

2000

3000

4500

6500

Atomizer rotary speed(rpm)

16000

12000-13000

11000-12000

Atomizing disc diameter(mm)

150

180-210

Customize based on production process

Electric heating max power(k w)

Equiped with other heating source

Dry powder recovery(%)

About 95

Length of land occupation(m)

12.5

13.5

14.5

Customize according to production process,

factory space condition and customers’ request.

Width of land occupation(m)

8

12

14

Height of spray tower(m)

10

11

15

Height of spray nozzle install (m)

3.2

3.2

3.2

Note: 1. these technical parameters just be FYI, detail please communicate with TOPTION engineer ([email protected]) to customize based on your actual production process.

2.Water evaporation capacity is related to material characteristic,content of solid and hot air inlet & outlet temperature.

3.You could choose heating method based on your local energy condition,choose dust collection and dusting method based

on material characteristic.

-

Applications of high speed centrifugal spray dryer:

1. Food industry: Amino acids, vitamins, egg powder, bone meal, spices, protein powder, milk powder, pig blood meal, soy sauce, coffee and tea, glucose, potassium sorbate, pectin, flavor spices, vegetable juice, yeast, starch, etc.2. Ceramics industry: Alumina, zirconia, magnesium oxide, titanium oxide, titanium magnesium, clay, China clay, all kinds of ferrite, metal oxide, etc.3. Chemistry products: Polyaluminium chloride, disperse dyes, reactive dyes, organic catalysts, white carbon black, washing powder, potassium fluoride, zinc sulfate, silica, sodium metasilicate, calcium carbonate, potassium sulfate, inorganic catalysts, all kinds of waste liquor, etc.

-

-

-