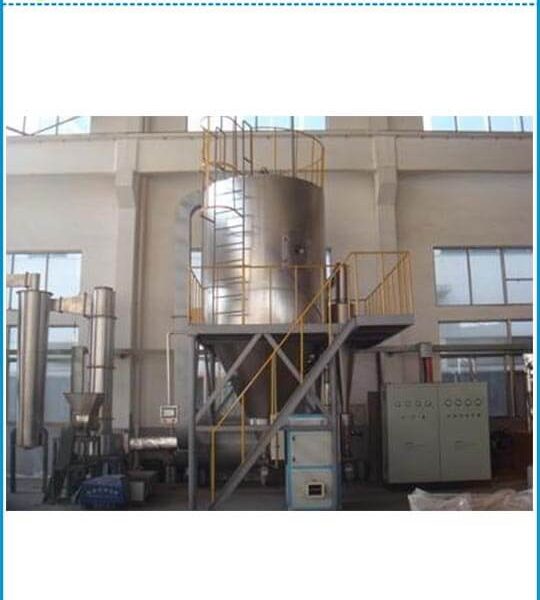

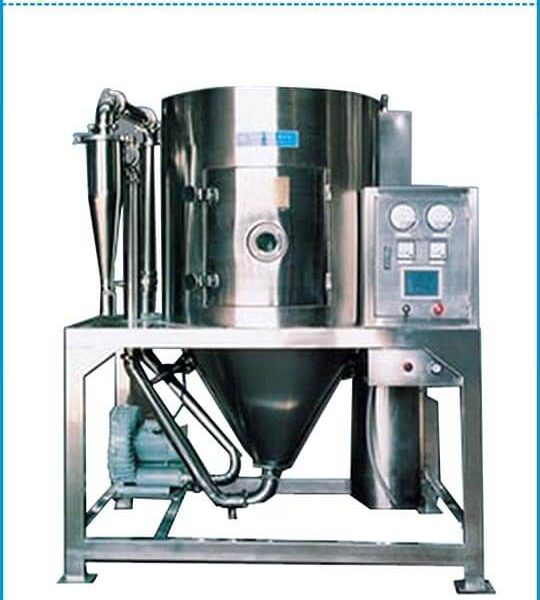

Industry Spray Drying Equipment Customize Spray Dryer China Manufacturer

-

1. Online and On-site training & installation service are available.

2. 2L 5L10L 20L hotsale fast delivery within 3days.

3. ISO CE certification.

- Description

Description

Description

-

Industry spray drying equipment customize drying capacity range:

5kg/h, 25kg/h, 50kg/h, 100kg/h, 150kg/h, 200kg/h, 500kg/h, 800kg/h, 1000kg/h, 2000kg/h, 3000kg/h, 4500kg/h, 6500kg/h.Centrifugal spray dryer application:

1.Food industry: Amino acids, vitamins, egg powder, bone meal, spices, protein powder, milk powder, pig blood meal, soy sauce, coffee and tea, glucose, potassium sorbate, pectin, flavor spices, vegetable juice, yeast, starch, etc.2.Chemistry products: Polyaluminium chloride, disperse dyes, reactive dyes, organic catalysts, white carbon black, washing powder, potassium fluoride, zinc sulfate, silica, sodium metasilicate, calcium carbonate, potassium sulfate, inorganic catalysts, all kinds of waste liquor, etc.3.Ceramics industry: Alumina, zirconia, magnesium oxide, titanium oxide, titanium magnesium, clay, China clay, all kinds of ferrite, metal oxide, etc.Advantages of spray drying equipment:

1.Fast drying speed, the material liquid after atomization, significantly increased its surface area, when contact with the hot air, can evaporate its 95% – 98% water in an instant, whole drying time just need a few seconds, so especially suitable for drying thermal sensitive material.2.Spray drying product has good uniformity, fluidity and solubility, powder or particle has higher purity and excellent quality.3.Spray dryer production process is simple, convenient operation and easy control. For 40%-60% moisture content liquid (special materials can be up to 90%), could spray drying to powder or particle in one time, and dried without crushing & screening, reduce the production process and improve product purity.4.The spray drying product particle size, bulk density and moisture can be adjusted by changing centrifugal spray dryer operating conditions, control and management both are convenient.Centrifugal spray dryer technical parameters:

-

TGZ-5

TGZ-25

TGZ-50

TGZ-100

TGZ-150

TGZ-200

Inlet temp.(℃)

140-350 Automatic control syste

Outlet temp.(℃)

80-90

Spray type

High speed centrifugal atomizer ( mechanical drive or stepless frequency control speed are optional )

Water evaporation capacity(kg/h)

5

25

50

100

150

200

Atomizer rotary speed(rpm)

25000

22000

21500

18000

16000

Atomizing disc diameter(mm)

60

120

150

Electric heating max power(k w)

8

31.5

60

81

99

Equiped with other heating source

Dry powder recovery(%)

About 95

Length of land occupation(m)

1.6

4

4.5

5.2

7

7.5

Width of land occupation(m)

1.1

2.7

2.8

3.5

5.5

6

Height of spray tower(m)

1.75

4.5

5.5

6.7

7.2

8

Height of spray nozzle install (m)

– –

2.5

2.5

3.2

3.2

3.2

Note: 1. these technical parameters just be FYI, detail please communicate with TOPTION engineer ([email protected]) to customize based on your actual production process.

2.Water evaporation capacity is related to material characteristic,content of solid and hot air inlet & outlet temperature.

3.You could choose heating method based on your local energy condition,choose dust collection and dusting method based on material characteristic.

-

-

TGZ-500

TGZ-800

TGZ-1000

TGZ-2000

TGZ-3000

TGZ-4500

TGZ-6500

Inlet temp.(℃)

140-350 Automatic control syste

Outlet temp.(℃)

80-90

Spray type

High speed centrifugal atomizer ( mechanical drive or stepless frequency control speed are optional )

Water evaporation capacity(kg/h)

500

800

1000

2000

3000

4500

6500

Atomizer rotary speed(rpm)

16000

12000-13000

11000-12000

Atomizing disc diameter(mm)

150

180-210

Customize based on production process

Electric heating max power(k w)

Equiped with other heating source

Dry powder recovery(%)

About 95

Length of land occupation(m)

12.5

13.5

14.5

Customize according to production process, factory space condition and customers’ request.

Width of land occupation(m)

8

12

14

Height of spray tower(m)

10

11

15

Height of spray nozzle install (m)

3.2

3.2

3.2

Note: 1. these technical parameters just be FYI, detail please communicate with TOPTION engineer ([email protected]) to customize based on your actual production process.

2.Water evaporation capacity is related to material characteristic,content of solid and hot air inlet & outlet temperature.

3.You could choose heating method based on your local energy condition,choose dust collection and dusting method based on material characteristic.

-

-

-