Lab Molecular Distillation Essential Oil Distillation Equipment

-

1. 0.06m2 evaporation area, pilot, industry type are optional.

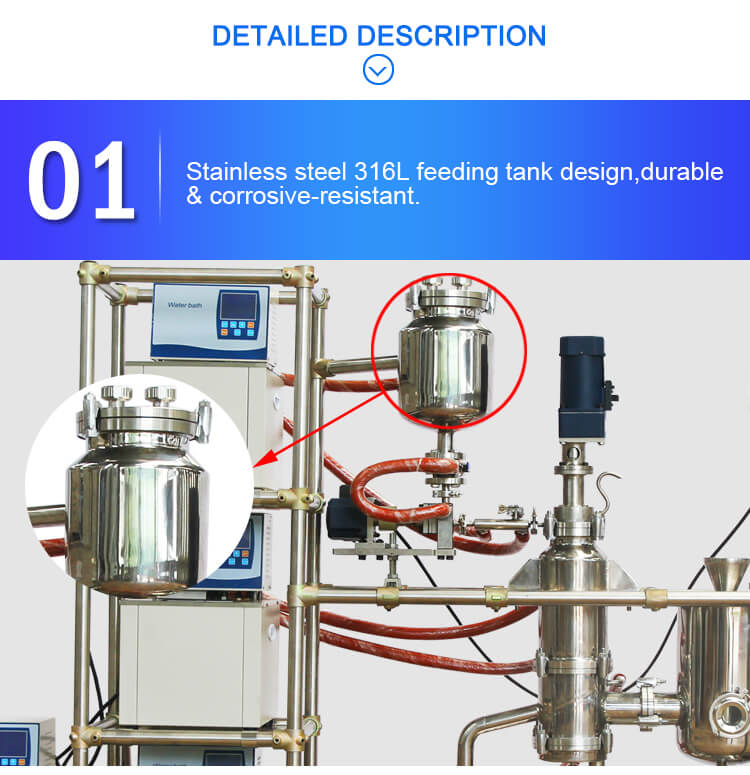

2. 3L stainless steel double-layer insulation feeding tank.

3. Continuous feeding of magnetic gear pump, 24h/7days continuously working.

- Description

Description

Description

-

Sample drawing of essential oil distillation equipment:

Lab molecular distillation essential oil distillation equipment.

-

Below a distillation plant for laboratory use is described. The plant is used for:

-Process development.

-Feasibility studies.

-Continuous distillation of smaller quantities.-For heat sensitive chemical, pharmaceutical and food products.

The achievable operating pressure may be as low as 0.001 mbar in the short path evaporator. (Depending on product and process).

-

Technical data of the molecular distillation unit:

Type of molecular distillation

MDS-6CE molecular distillation equipment

Maximum distillation temperature

300 °C

Minimal achievable operating pressure

(depending on product)

< 0.001mbar with rotary vane pump and oil diffusion vacuum pump.

Throughput (depending on product)

1 – 3 kg/h

Evaporation surface

0.06 m²

Surface of internal condenser

0.1 m²

Surface of external condenser

0.1 m²

Wiped film system

Scraper type film scraping rotor

Maximum viscosity of product can be processed

Under operating temperature: 5000 centipoise.

-

1.Material feeding system:

-Feed tank: 1L jacketed glass tank.

-High precision gear pump feed (3-15L/H). Feed tank jacket design, can be heated and achieve heat preservation by circulating heat conduction oil.

2.Short path evaporator:

-Material (contact with products): S304 stainless steel.-Evaporator surface: 0.06㎡.-The heating medium of evaporator: Conduction oil.-Design temperature of evaporator jacket: 350℃.-Design pressure of evaporator jacket: 0.4Mpa.-Heating segment: 1.-Film forming system: Self-cleaning roller type film forming system.

-Motor & reduction gears: Electrodeless reduction gears, 0.12KW.

-Sealing type: mechanical seal.Note: The end of the pipe mouth is also a jacket design, no heating dead Angle, make heat preservation be more comprehensive.3.Heavier component discharge system:

Continuous discharge gear pump (3-15L/H).4.Lighter component discharge system:

-1set condenser whose heat exchange area is 0.1㎡, cooling and collecting the distillation extract light component, material is S304 stainless steel.

-Continuous discharge gear pump (3-15L/H).

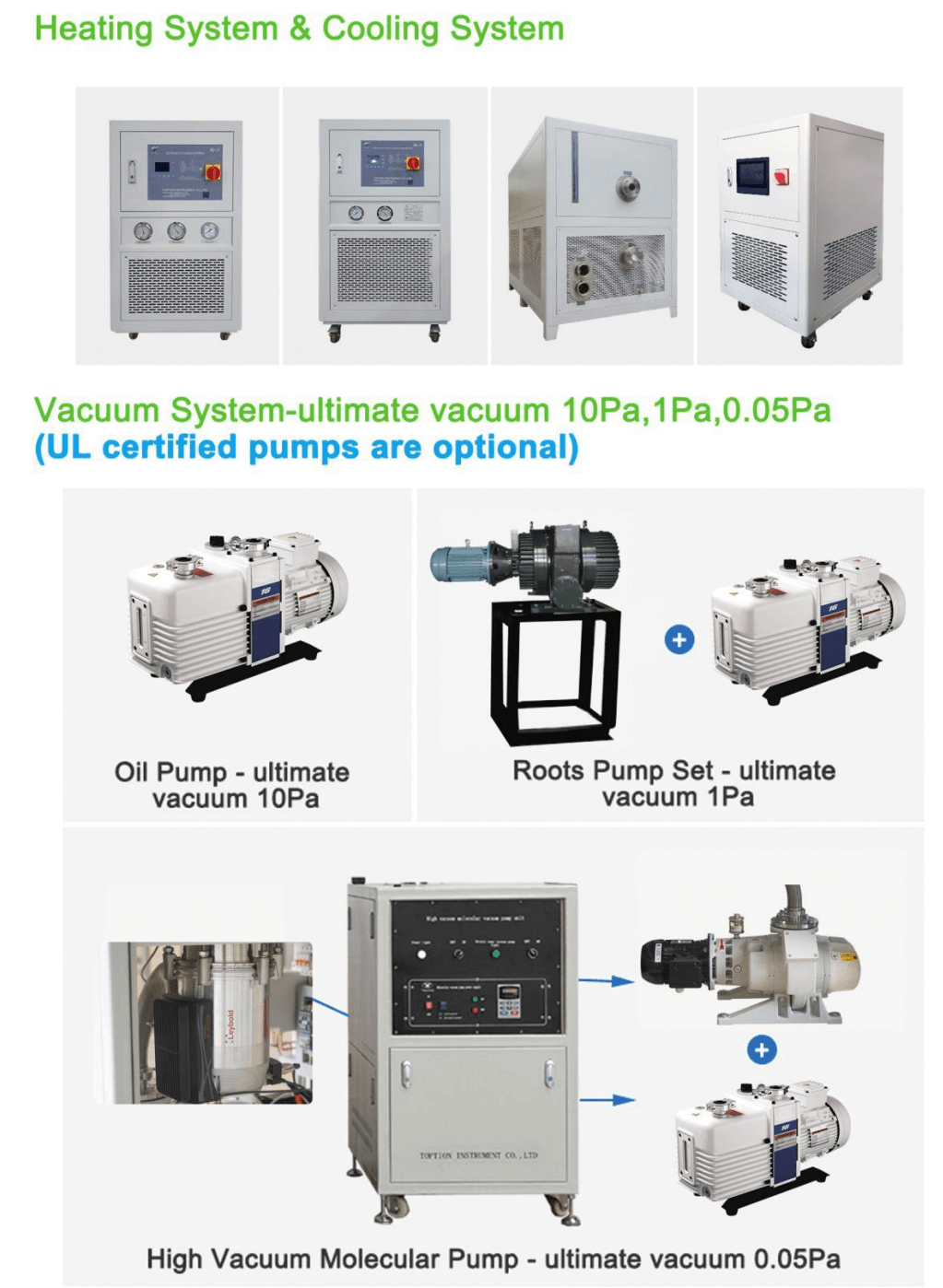

5.Heating & Cooling Unit and vacuum system of molecular distillation equipment -

TOPTION brand laboratory essential oil distillation equipment

, through CE certification, ISO approved,reliable quality be your TOP OPTION partner to growing your cbd oil business -

Welcome visit our molecular distillation equipment factory, contact info@toptionreactor.com

now, we will reply you within 1-6hours. -

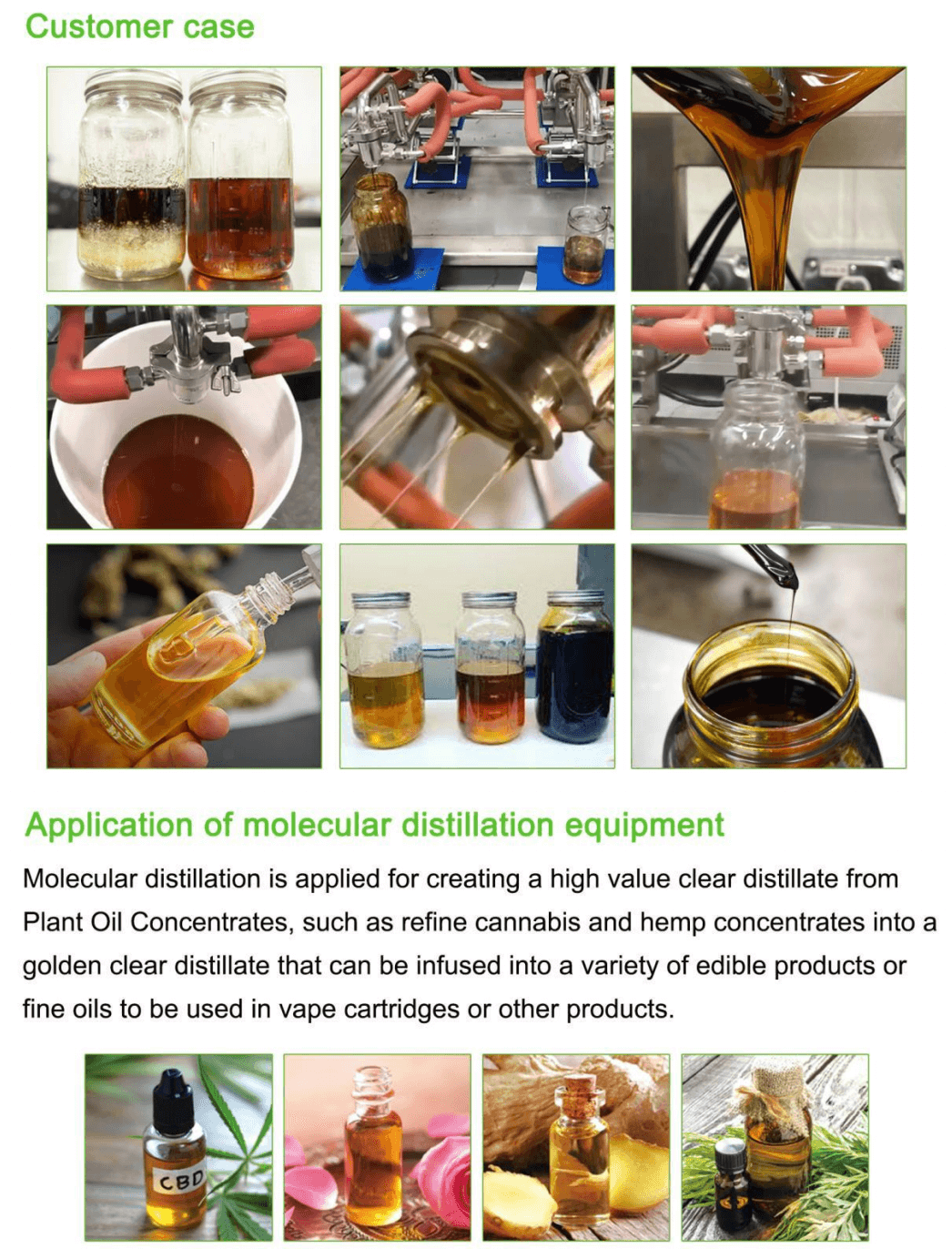

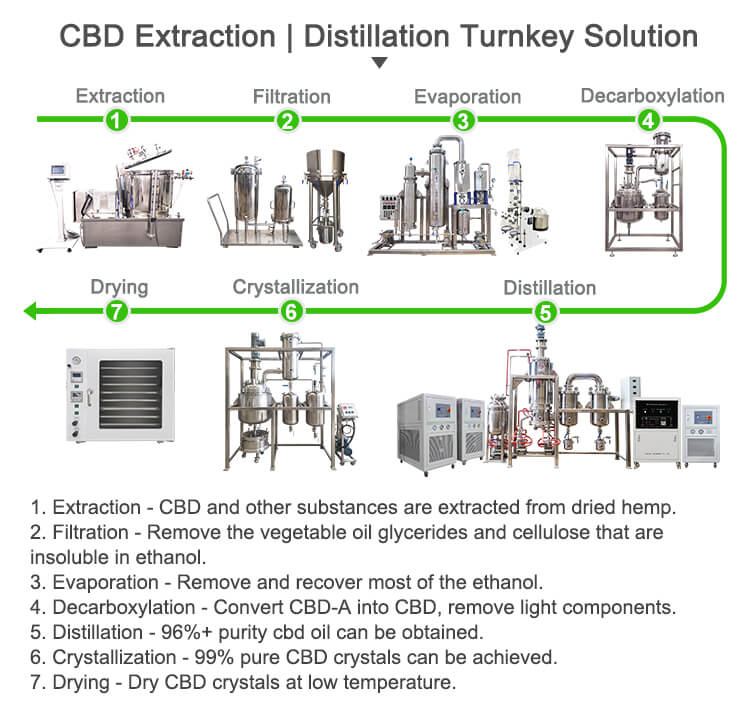

cbd oil short path molecular distillation one stop solution