Nutsche filter dryer price

-

1. Make the material finish filtering, washing and drying process in an airtight container equipment.

2. With more than 16 years production experience, provide professional customize, global OEM.

3. Welcome factory visit or on-site install service is available.

Request a Quote

- Description

Description

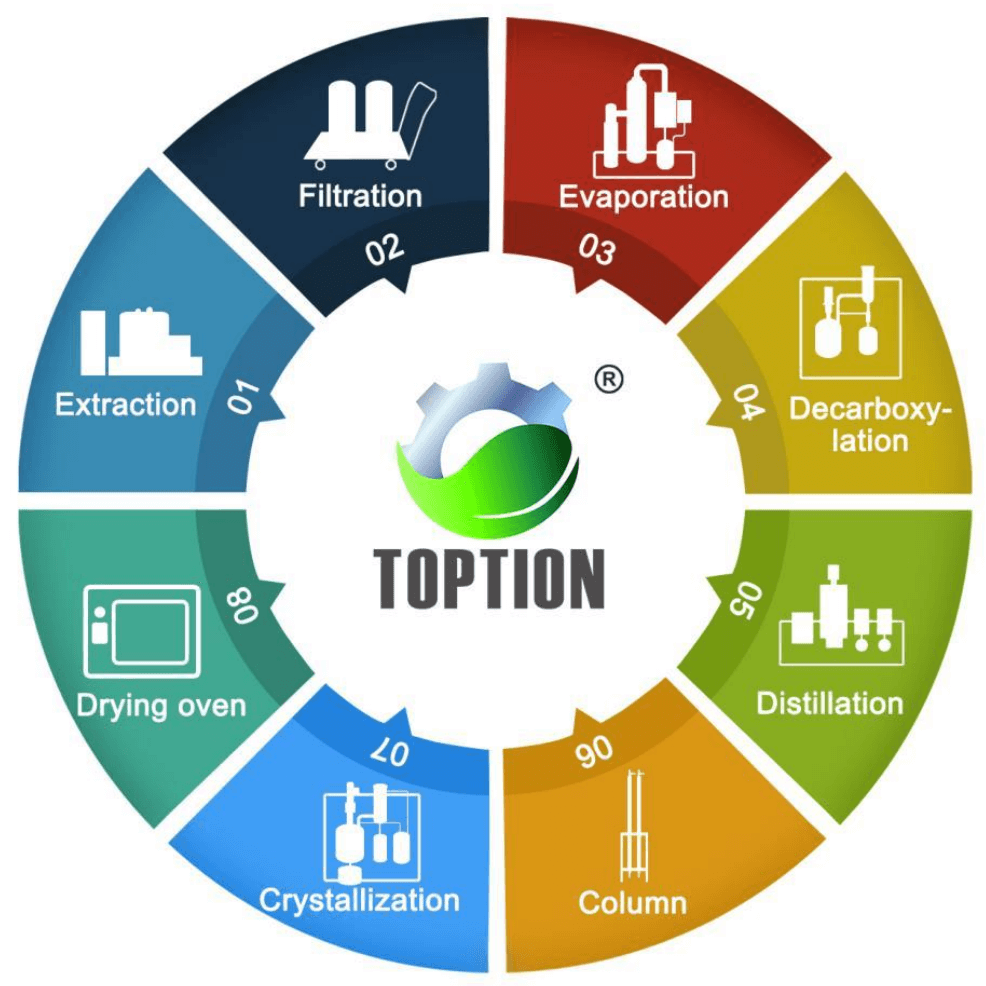

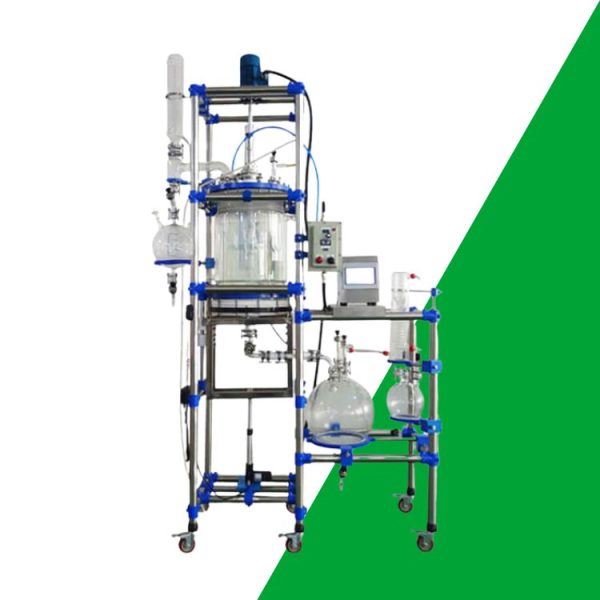

TOPTION chemcial glass reactor has ISO & CE certification, you could use laboratory glass reactor to do synthesis of new materials, homogeneous mixing reaction, extraction and purification, distillation and purification samples.

Description

-

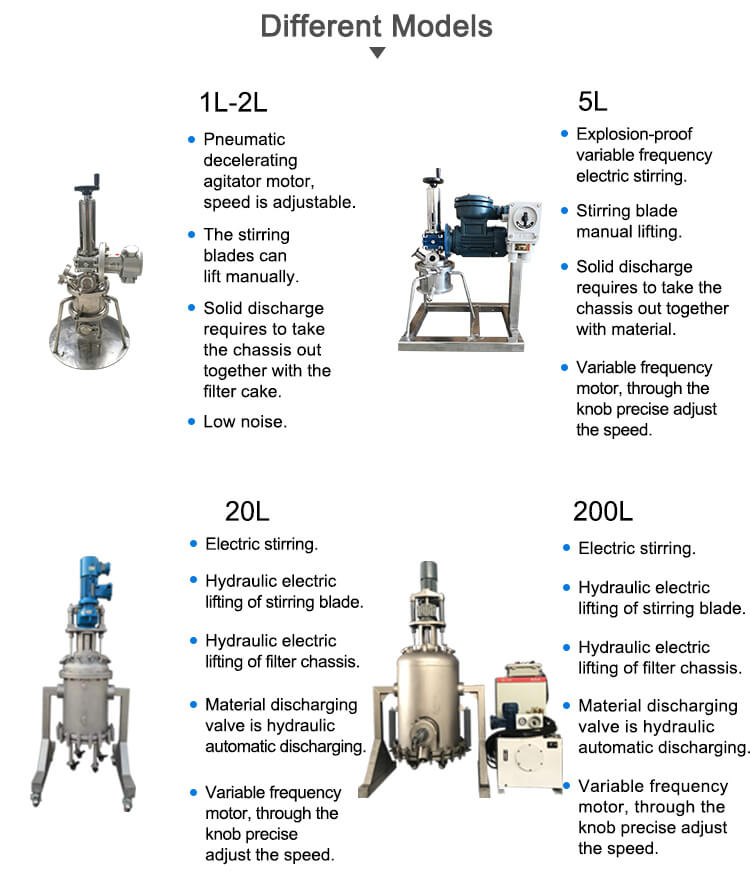

Nutsche filter dryer price

TOPTION this type new design nutsche filter dryer gather “Filtration, Washing, Drying” function in one body, you can make the material finish filtering, washing and drying process only in an airtight container equipment, make your research more accurate & efficient, save your cost & time.

-

-

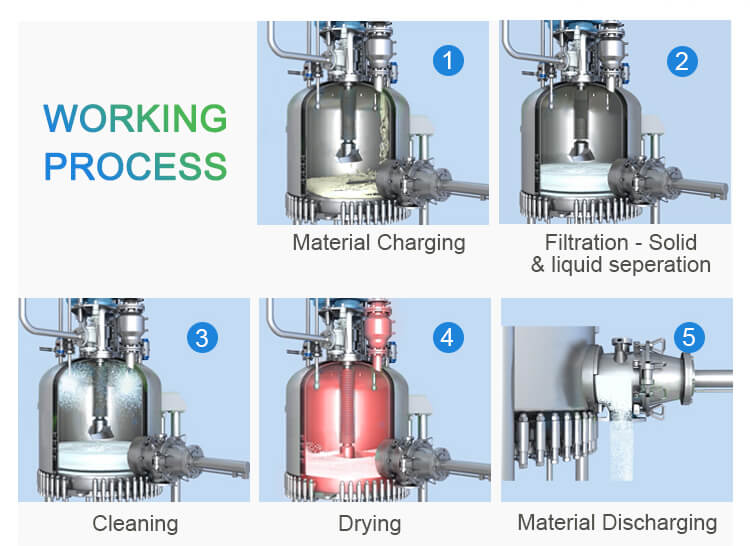

The working process of nutsche filter dryer

1. Filtration stage: separation of filter cake and mother liquor.The thickness of filter cake can reach 600mm.2. Washing stage: further purification of filter cake, cleaning of residual mother liquor & pre-dehydration. Filter cake and washing were mixed layer by layer with lifting agitator. Finally, the slurry and suspension filter cake were fully washed.3. Drying stages: filter cake dehydration processing, filter cake in the blender scratch step by step a loose at the same time, side wall, the bottom of the filter plate, and mixing blade of filter cake is heated at the same time, the wet rapid evaporation drying effect, speed up the evaporation, by using the method of equipment in vacuum by joining the media such as nitrogen after processing take wet evaporation, to accelerate the drying of material, improve the effect of drying.4. Unloading stage: dry materials are automatically discharged from the side outlet through the reverse drive of s-type stirring paddle.Professional customize nutsche filter dryer, contact info@toptionreactor.com

24h/7days service. -

-