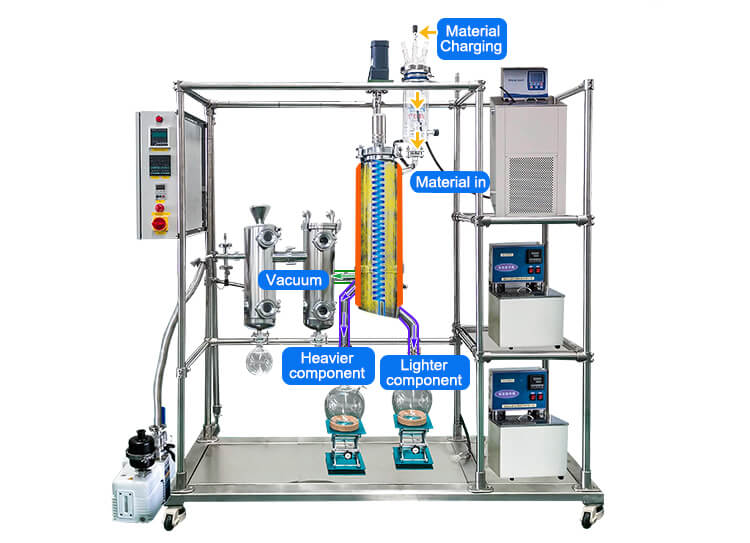

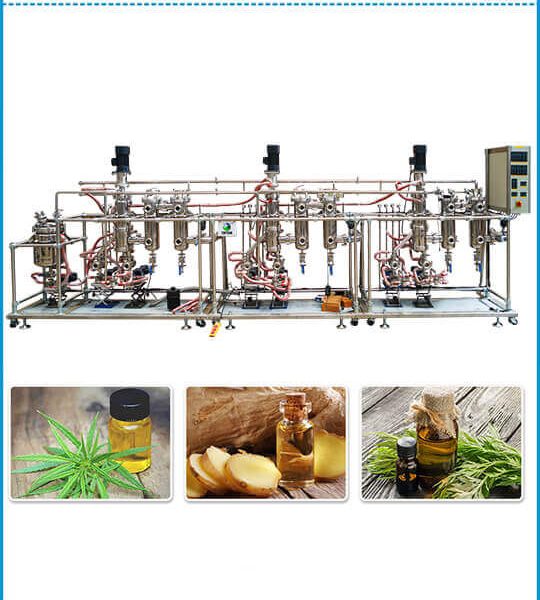

Short Path Molecular Distillation Equipment

-

1. Through precision gear pump feeding material, especially suitable for excessive material impurities.

2. 24h/7days continuously working, high throughout.

3. Applicable to the selection of efficiency in research and batch production.

- Description

Description

Description

-

TOPTION this type single stage short path distillation plant is for laboratory use:

1. Process development.

2. Feasibility studies.

3. Continuous distillation of smaller quantities.

4. For heat sensitive chemical, pharmaceutical and food products.

The achievable operating pressure may be as low as 0.001 mbar in the short path evaporator. (Depending on product and process).

-

Technical parameters of the molecular distillation equipment:

Type of molecular distillation

MDS-10CE short path molecular distillation

Maximum distillation temperature

300 °C

Minimal achievable operating pressure

(depending on product)

< 0.001mbar with rotary vane pump and oil diffusion vacuum pump.

Throughput (depending on product)

5 – 12 kg/h

Evaporation surface

0.1 m²

Surface of internal condenser

0.15 m²

Surface of external condenser

0.15 m²

Wiped film system

Scraper type film scraping rotor

Maximum viscosity of product can be processed

Under operating temperature:5000 centipoise.

-

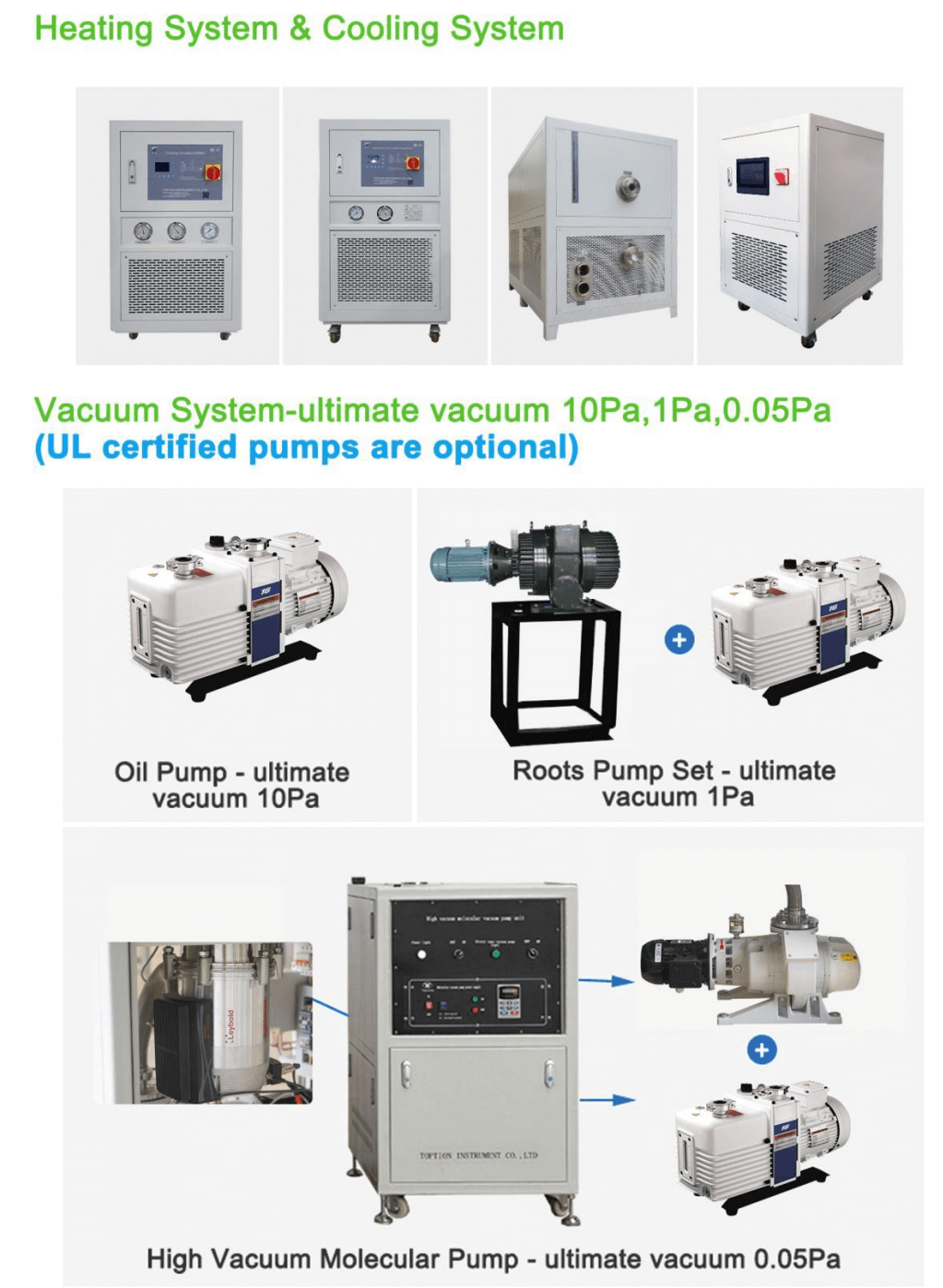

Whole set molecular distillation equipment include high vacuum molecular pump, heating & cooling circulators.

-

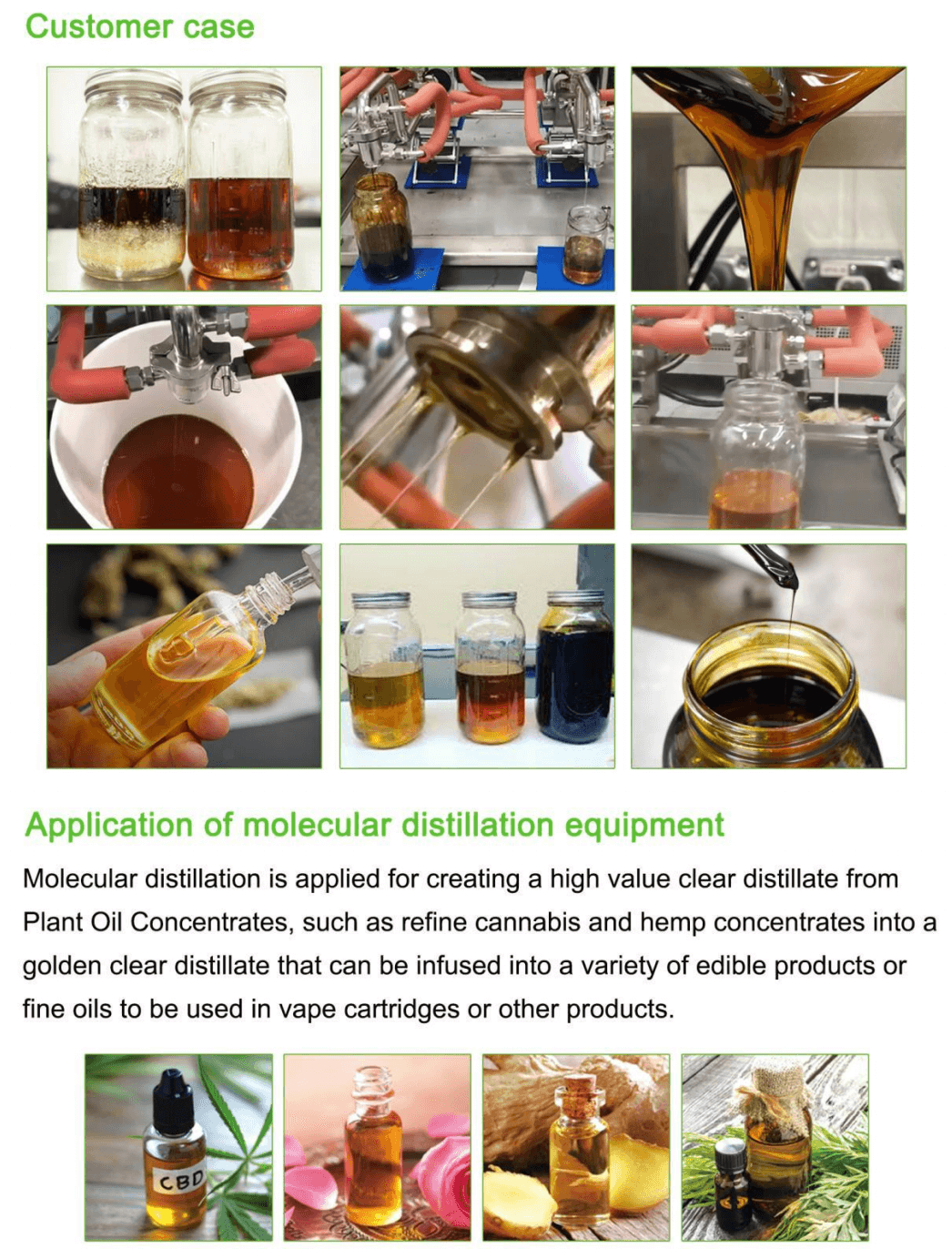

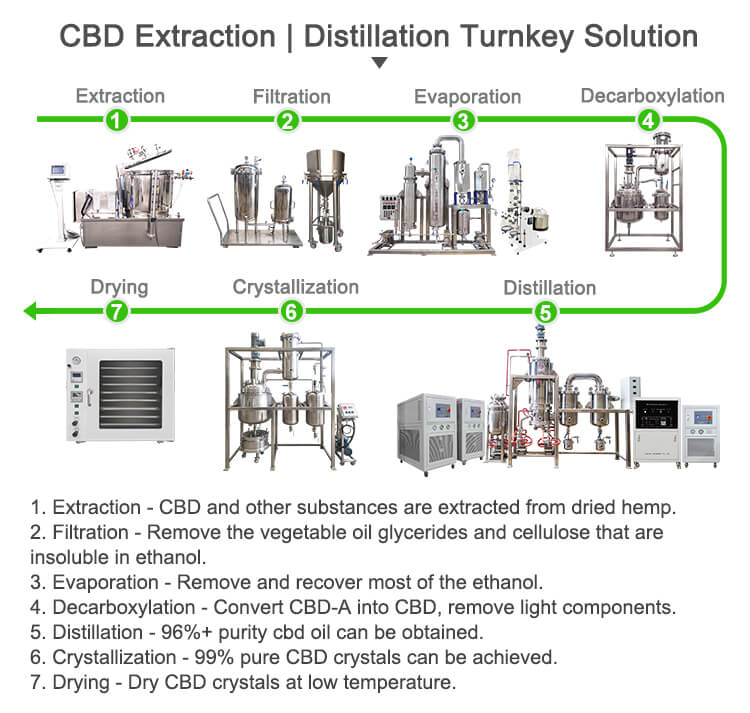

The application of this laboratory short path molecular distillation setup:

1. Thermal separation of heat sensitive chemical compounds.

2. The purification of organic synthetic material.

3. The separation of effective components from the biological extracting solution.

4. The recycling of industrial waste.

5. Remove toxic substances in the food industry.

6. The organic compounds’ decoloring, and eliminate the unusual smell.

7. High precision to remove residual solvent in chemical compound. -

Visit TOPTION molecular distillation equipment

factory in China, welcome contact info@toptionreactor.com

free consultation.