Short path thin film distillation

-

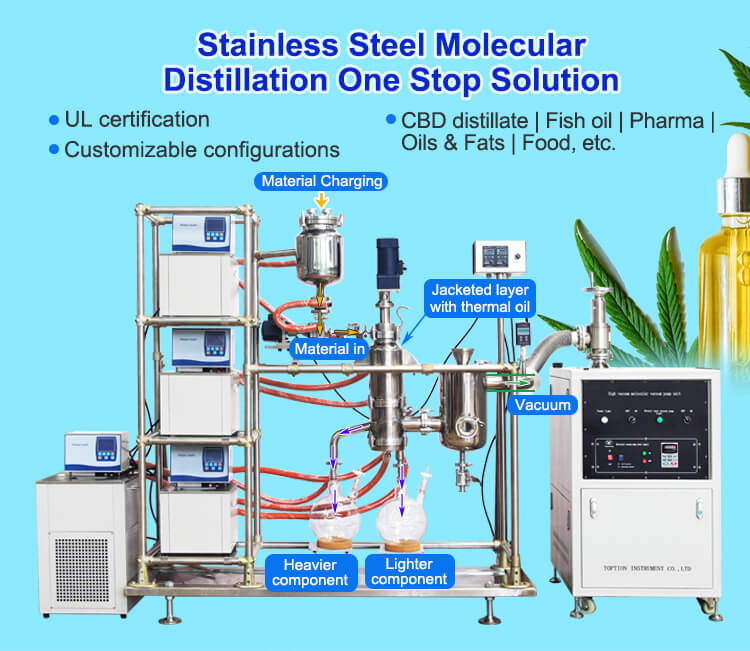

1. 10L jacketed glass material feeding tank.

2. S304 stainless steel evaporator surface: 0.1㎡.

3. Heating & cooling system, vacuum system equipped well.

- Description

Description

Description

-

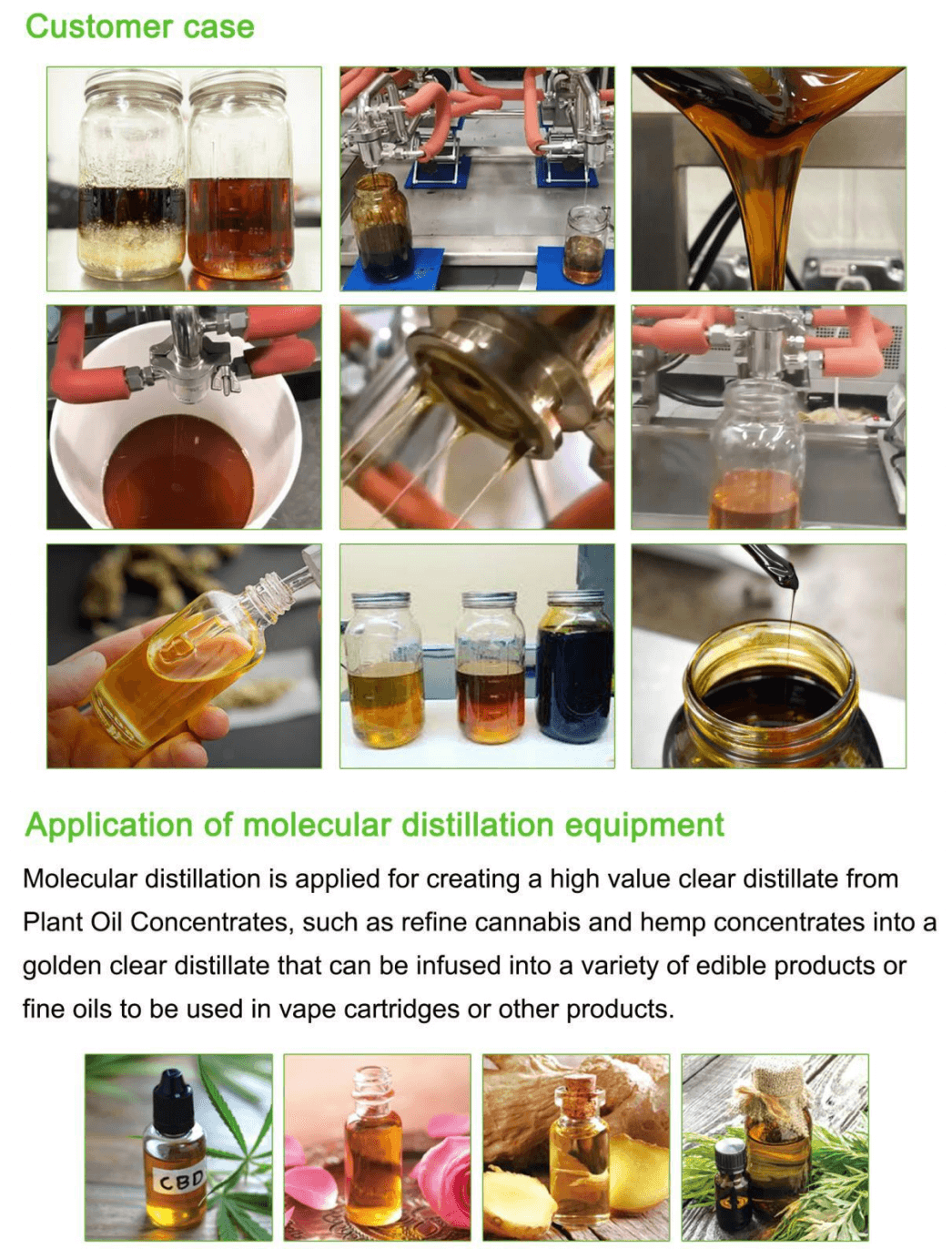

Short path thin film distillation system is a comparatively new separation technology, which can separate liquid-liquid mixture under temperature that is far lower than boiling point by the difference of mean free path of molecular under high vacuum condition.

Short path thin film distillation molecular distillation technology is suitable to separate substance of high boiling point, heat sensitive and easy to be oxidized.

-

Technical parameters of MDS-6A short path thin film distillation

Main body

Model

Material tank

1L jacketed glass tank

Material charging

Differential pressure PTFE valve.

Feed rate 0.5L~3L/H

Evaporator

Evaporation area 0.06㎡

Film forming way:scraper (roller is optional)

Material:316L

Mechanical seal (Magnetic seal is optional)

Film forming motor:200W motor, electronic speed regulation.

Cold trap

1. 0.2㎡chiller cooling cold trap

2. 1L liquid nitrogen cold trap

3. Dual-purpose(chiller & liquid nitrogen cold trap dual purpose).

Choose 1 in above 3 types

Heavier component discharge

29# Grinding mouth adapter

5L glass bottle 1pcs, bottle holder 1pcs

Lifting table 1pcs

Lighter component discharge

29# Grinding mouth adapter

5L glass bottle 1pcs, bottle holder 1pcs

Lifting table 1 pcs

Material pipeline

Jacketed insulation

Shelf & assemble

304 stainless steel pipe

Accessory

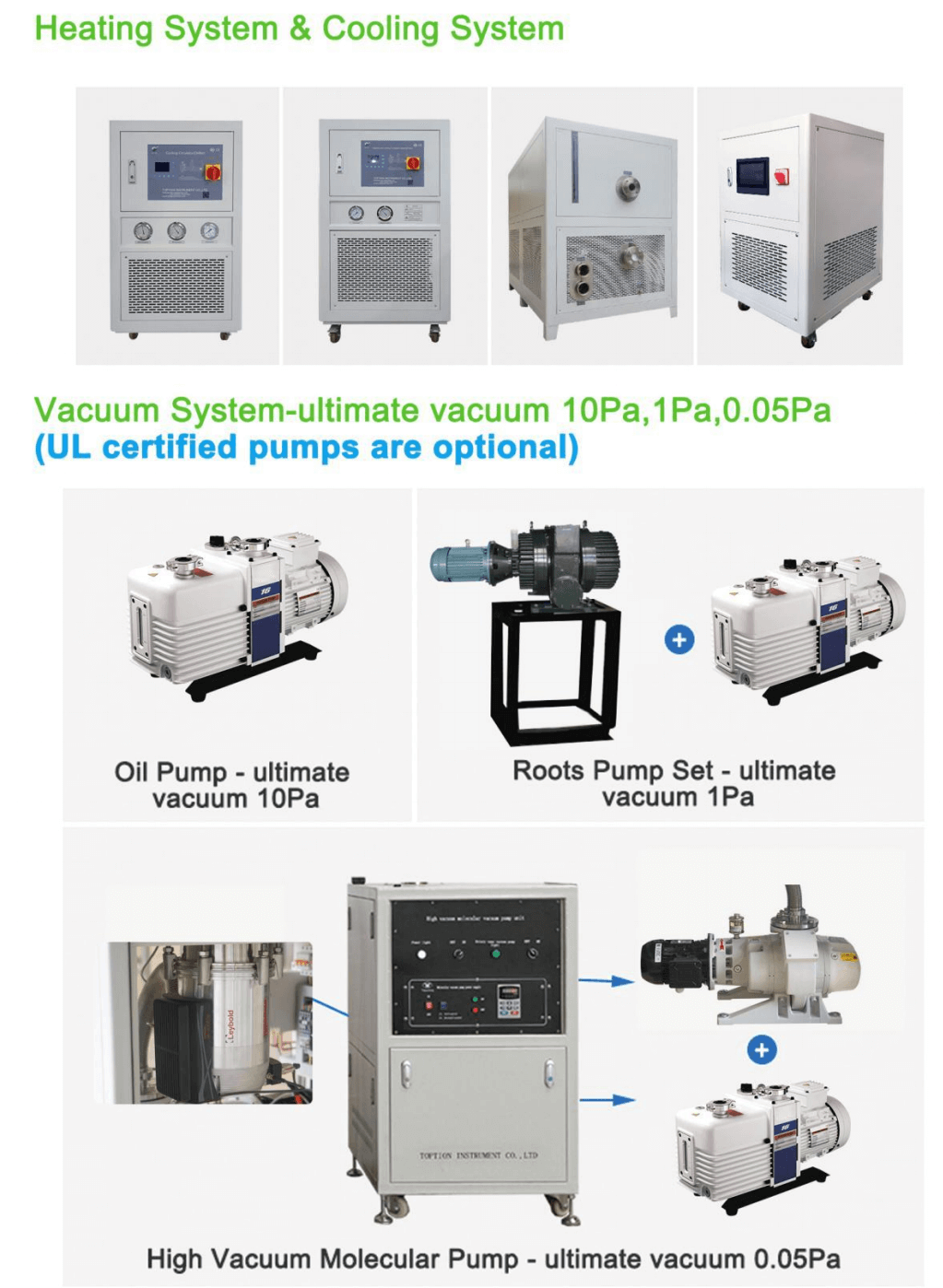

Vacuum

1. No-load < 10PA

2. No-load < 5PA

3. No-load < 0.01PA rotary vane molecular pump set (Single phase 220V)

Vacuum gauge

Resistance / thermo couple vacuum transmitter

Main evaporator heating

300℃/3KW

Raw material section insulation

200℃/1.5KW

Heavier component

insulation

200℃/1.5KW

Lighter componentcondensation & insulation

(CBD lighter component could share with material feeding tank)

Internal condenser — High & low temperature all-in-one machine

Insulation —200℃/1.5KW

External cold trap cooling

1. Liquid nitrogen cold trap

Or 2. Chiller

-

Main features of TOPTION molecular distillation unit:

1. Material feeding tank: 10L jacketed glass tank. – High precision gear pump feeding (3-15L/H).

2. Short path evaporator material (contact with products): S304 stainless steel. Evaporator surface: 0.1㎡ .

3. Heavier component discharge system & Lighter component discharge system both are 29# Internal grinding mouth glass collection bottle and vent valve collection material: 5L.

4. Has 1set condenser whose heat exchange surface is 0.15㎡, material is SS304 stainless steel.

5.Heating & Cooling Unit are equipped well.

6. Vacuum system:

-6.1 Vacuum degree 10pa, need to equipped with TRP-36 vacuum pump: 9L/S.

-6.2 Vacuum degree 1pa, need equipped with TPR-36 vacuum pump + roots pump unit ZJP-150S.

-6.3 Vacuum degree 0.1pa, need to equipped with oil pump + oil diffusion pump unit T150.

-

7.CE certification, ISO approved, reliable quality manufacturing 15 years.

-

Welcome global customers visit our plant oil molecular distillation equipment factory, contact info@toptionreactor.com

24h/7days online service.