TPV-100G top-press in-situ vacuum freeze dryer

-

1.Be widely used in medicine, pharmacy, biology research, chemical industry and food production, ect.

2.Goods are easier for long-term preservation after freezing-drying processing.

3.They can be restored to the original state and mantain its chemical and biological charateristics after being watered.

- Description

Description

Description

-

Vacuum freeze dryer

is widely used in medicine, pharmacy, biology research, chemical industry and food production, etc.Goods are easier for long-term preservaction after freezing-drying processing, they can be restored to the original state and maintain its chemical and biological characteristics after being watered.

TPV series In-situ freeze dryer changes the traditional complicated operation, prevents the pollution of the material and realizes the dry sublimation automation. It has electric heating shelf, is suitable for freeze drying experiment in laboratory or pilot scale.

-

-

-

-

-

Technical parameters of freeze drying machine

ModelUnit

TPV-30G

TPV-50G

TPV-100G

Specification

Top-press

Top-press

Top-press

Drying chamber

Freeze-drying area

㎡

0.31

0.5

1.15

Layers of partition board

Layers

3+1

3+1

4+1

Temp range of partition board

℃

-50℃ ~ +70℃

Temp difference of partition board

℃

±1 (in balance)

Space between partition boards

mm

70

100

100

Size of partition board

mm

300*340*20

410*410*20

480*600*20

ï¿ 22mm penicillin bottle

Pcs

546

1056

2428

ï¿ 16mm penicillin bottle

Pcs

1080

2046

4706

ï¿ 12mm penicillin bottle

Pcs

1950

3690

8400

Cold trap

Cold trap temperature

℃

≤-70℃

Water-capture capability

Kg

6

10

15

Liquid in tray

L

3

5

10

Defrost stytle

Electric defrost

Dimension

mm

1230*830*1430

1165*1310*1950

1330*1310*2200

Weight

Kg

700

900

1050

-

Main features of freeze drying equipment

1. Silicone oil heating in-situ vacuum freeze dryer.

2. The process of pre-freezing and drying finishes in situ. The freeze dryer is equipped with observation windows and the drying process is automatic.

3. The Temperature error is less than or equal 1℃. The drying effect is uniform.

4. The partition-board temperature is adjustable and controlled.

5. Stored 32programs, each program can be set up 36 segments, correct program data in computing, memorize the drying curve.

6. The drying chamber and cold trap is separated so the water-capture capability is higher and the drying time is shorter.

7. Touching-screen operation, PID controlling, displaying drying curve.

8. The sample tray is square so it’s easy to clean and operate.

9. Configuration of the inflation valve, rechargeable dry inert gas.

10. The drying chamber adopts transparent organic glass door the changing process of material is clear.

11. The test device is optional.

12. Vacuum pump of freeze dryer is available.

-

ISO & CE quality certification, products’ quality management system, for every delivery instrument, we have professional quality manager team to cheak, then sign product certification and warranty card. Protect your research and business safe. Welcome visit TOPTION

factory. -

-

-

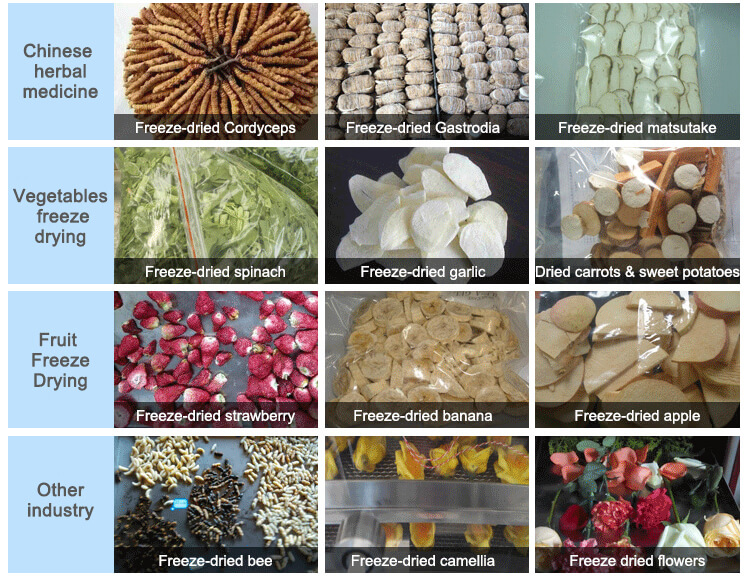

Goods are easier for long-term preservaction after freezing-drying processing, they can be restored to the original state and maintain its chemical and biological characteristics after being watered. The below is the vacuum freeze dryer casefor food, fruit, vegetable, meat, herb, alga, sea food,flower,etc.

-

As star lab solution provider, we believe, only the most excellent quality, most leading technology, most complete solution and most professional service, could make TOPTION mission and vision come true. For vacuum freeze dryer, TOPTION has more than 10 years professional development experience, mature technology is the base of our quality guarantee.

-

-

-

We are a young, professional and creative team,

We are customer-centric and responsible team.

Our mission: make your research more accurate and efficient.

Our vision: Become the world’s most competitive lab solution provider.

Our value: Sharing & win-win, customer success, be thankful, keep growing, innovation and responsible.

-

TOPTION as professional vacuum freeze dryer manufacturer, with more than 16 years freeze drying technology development, support freeze drying machine customize for global customers, ISO & CE certification high quality guarantee, welcome contact info@toptionreactor.com

24h/7days service.