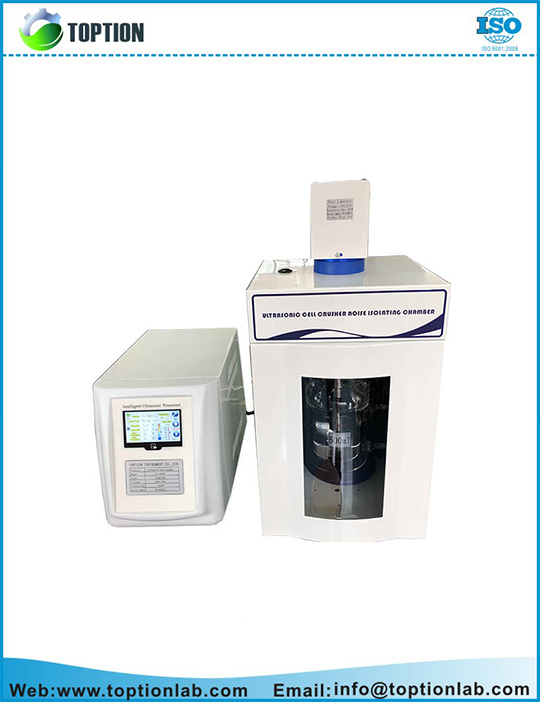

Ultrasonic Material Dispenser Ultrasonic Cavitation Treatment

-

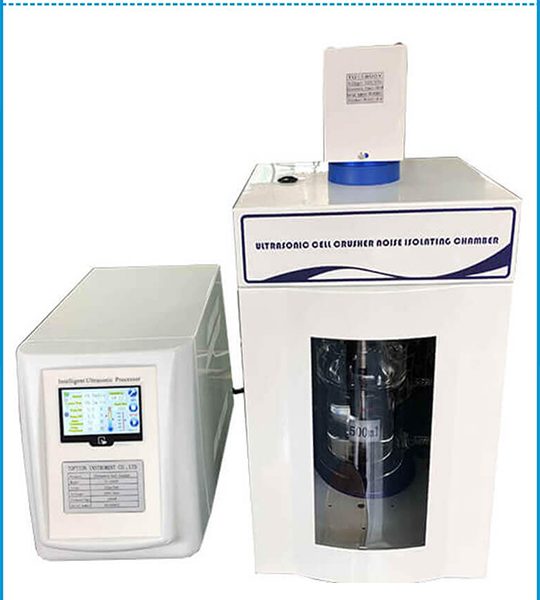

Most suitable to disperse nano materials (graphene,silicon dioxide,etc).

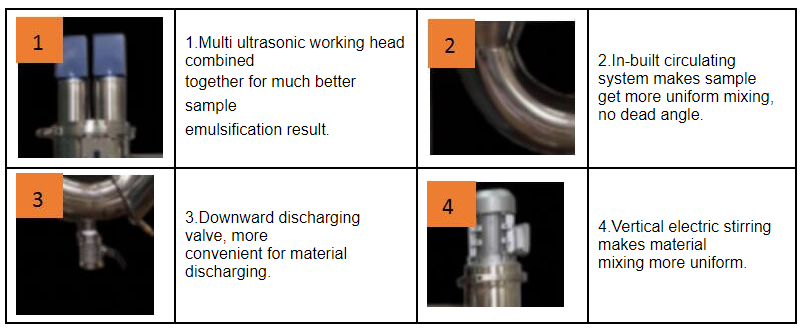

Multi ultrasonic working head combined together for better sample emulsification result.

Uniform mixing, no dead angle.

- Description

Description

Description

-

Ultrasonic material dispenser is also popular as ultrasonic emulsification reactor, stainless steel ultrasonic reactor, which through its “cavitation effect” to realize the emulsification of oil blended with water, emulsification of water mixed with oil, the mixture and homogenization of dispersed phase and continuous phase, it’s modern chemical technology to instead of propeller, colloid mill and other traditional emulsification technology.

-

TUER–5SUS /

TUER–5SUD

TUER-10SUS /

TUER-10SUD

TUER-20SUS /

TUER-20SUD

Ultrasound Method

Energy-gathered circulation multiple-step type

Capacity(L)

5

10

20

Stir Motor Power(W)

100

150

200

Ultrasonic Frequency

20KHz

20KHz

20KHz

Standard Ultrasonic Probe

ï¿ 20*1

ï¿ 20*2

ï¿ 20*3

Ultrasonic Power(w)

50~1200 Adjustable

100~2400 Adjustable

200~3600 Adjustable

Circulation Stirring Rate (rpm)

0~1000 Integrated

Digital Display,

Stepless Timing

0~1000 Integrated

Digital Display,

Stepless Timing

0~1000 Integrated

Digital Display,

Stepless Timing

Controlled Temperature ℃

(Optional)0–100

0–100

0–100

Reactor Material

SS304/Glass

SS304/Glass

Applicable Medium

Volatility /

Fixed Hydrocarbon

Volatility /

Fixed Hydrocarbon

Volatility /

Fixed Hydrocarbon

Application

Laboratory & Pilot

Laboratory & Pilot

Pilot

Note: Professional Customization is provided, high temp. device, low temp. device, constant temp. device are available (-5℃ ~ 100℃).

Model: S – stainless steel material; U- “U” shape design; S – single layer; D – double layer.