-

7L Pilot Freeze Dryer, Lyophilization Machine Factory China

TOPTION freeze drying technology is known as lyophilisation, lyophilization, or cryodesiccation, it’s a dehydration process typically used to preserve a perishable material or make the material more convenient for transport, and long period strorage.

-

-

-

-

The main advantages of this type in-situ vacuum freeze dryer:

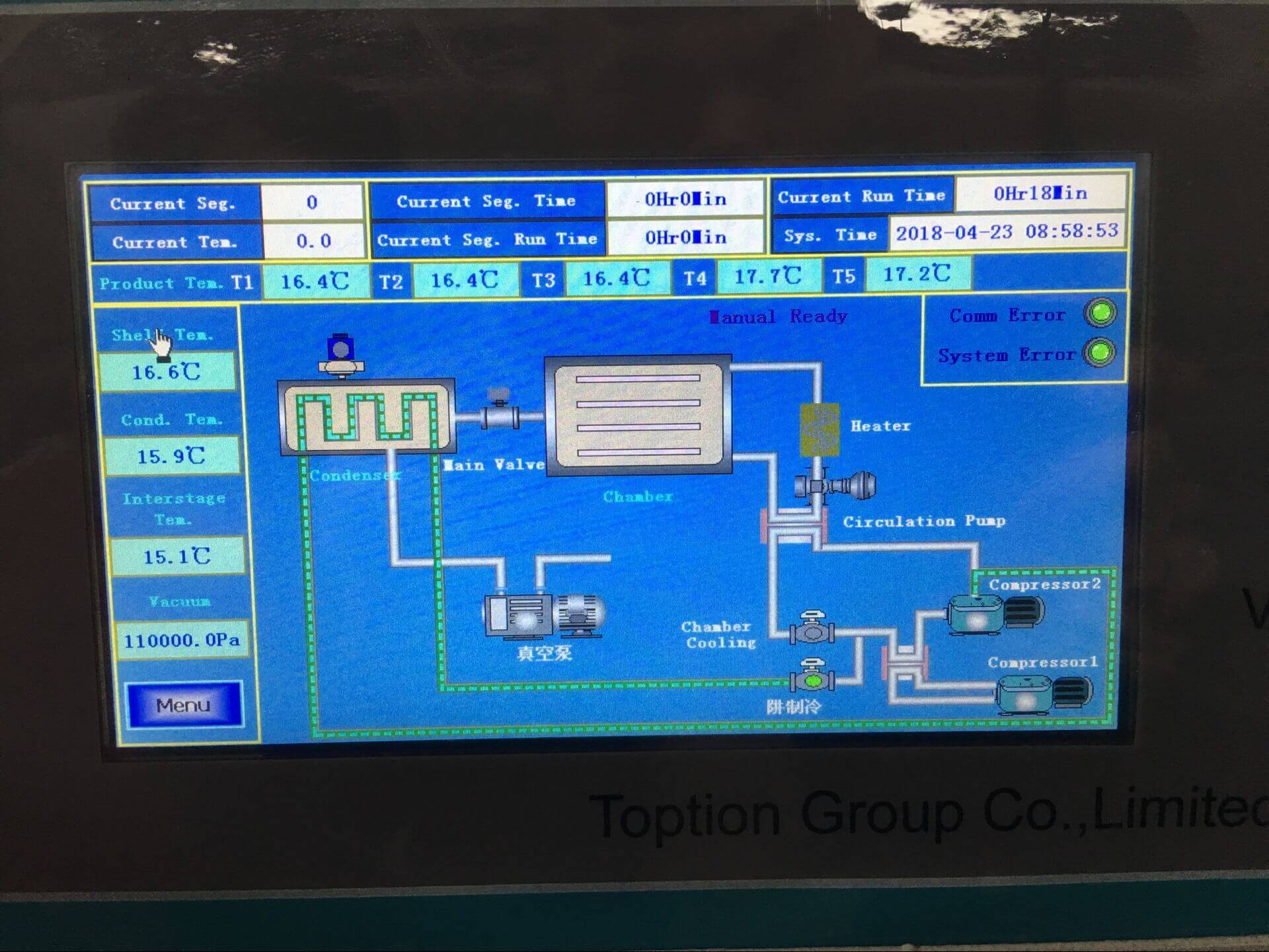

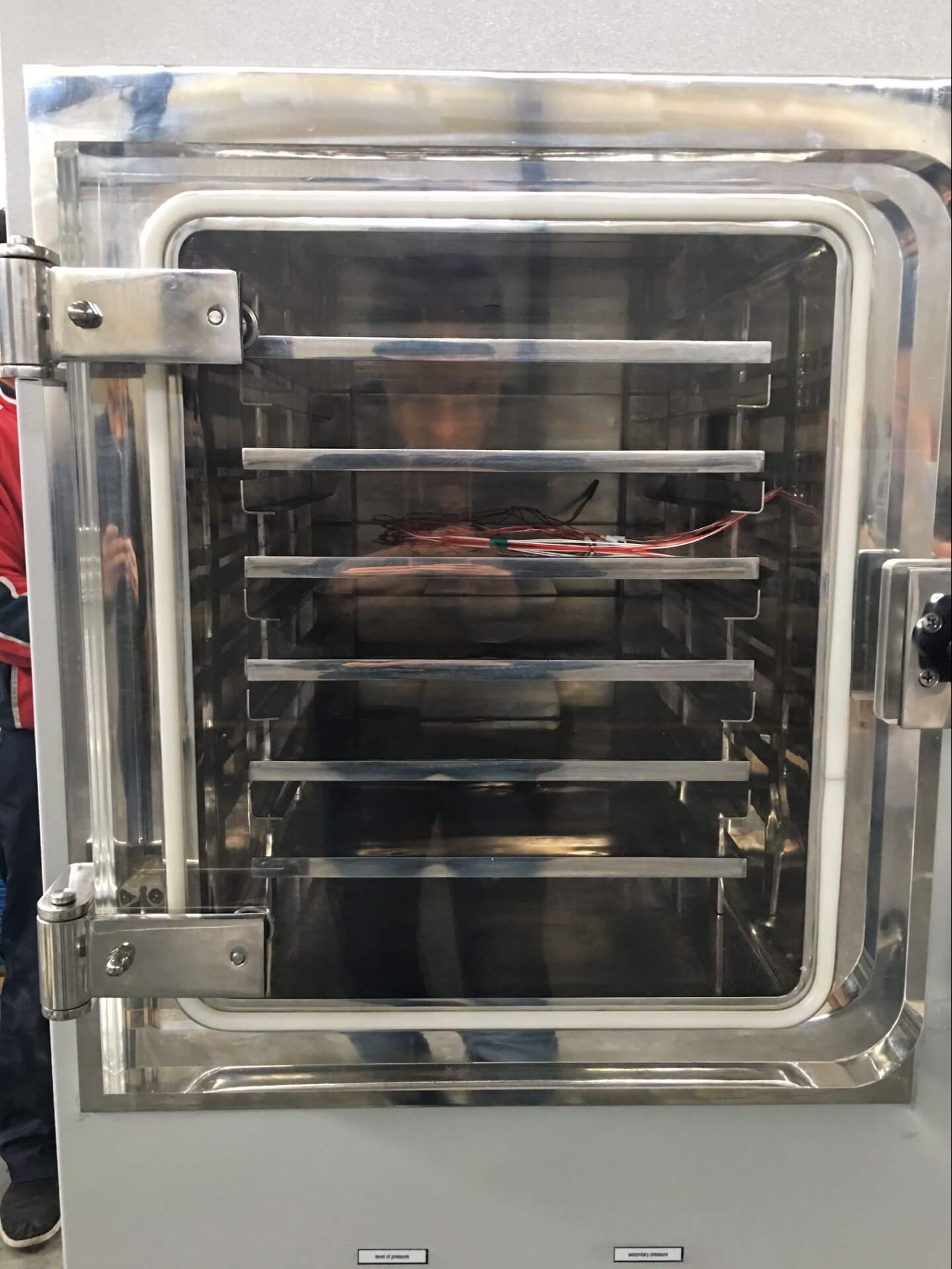

The process of pre-freezing and drying finishes in situ. The freeze dryer is equipped with observation windows and the drying process is automatic.

1. The Temperature error is less than or equal 1℃. The drying effect is uniform.

2. The partition-board temperature is adjustable and controlled.

3. Stored 32programs, each program can be set up 36 segments, correct program data in computing, memorize the drying curve.

-

-

4. The drying chamber and cold trap is separated so the water-capture capability is higher and the drying time is shorter.

5. Touching-screen operation, PID controlling, displaying drying curve.

-

-

6. The sample tray is square so it’s easy to clean and operate.

-

-

-

7. Configuration of the inflation valve, rechargeable dry inert gas.

8. The drying chamber adopts transparent organic glass door the changing process of material is clear.

9. The test device is optional.

Technical parameters of 7L pilot freeze dryer:

-

Item

TPV-50F

Freeze drying area

0.69 ㎡

Condenser temperature

<-75℃

Vacuum degree

<5Pa Water capture capacity

> 10Kg/24h

Cooling mode

Air cooling, ventilation, room temperature 25 ℃ or less

Shelf size

480×360mm*4+1

Power

5500W

Weight

600kg

Dimension (mm)

1000×785×1420

Bulk capacity Thickness:10mm

7L

Vials loading

number(pcs)Ф12mm:4676

Ф16mm:2772

Ф22mm:1440

-

Want know more detail paramters of vacuum freeze dryer, or this type freeze drying machine is not suitable for you, want to customize freeze dryer lyophilizer with special requirements, welcome contact [email protected]

to get free consultation.