-

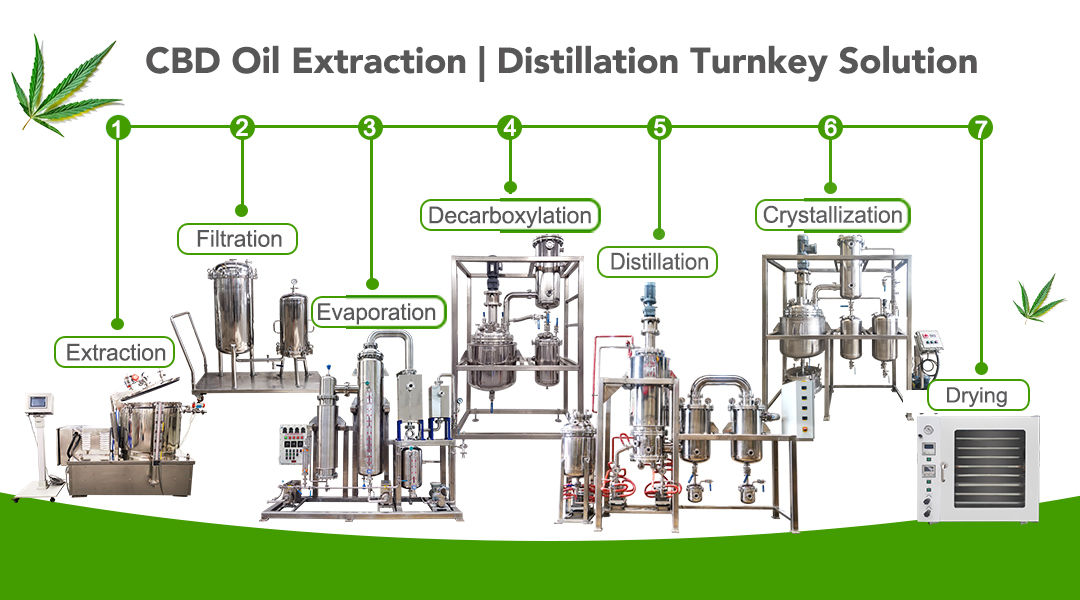

TOPTION this customized cbd production line

has been highly recognized by our customer after installation and commissioning. At present, the packaging steps have been completed, and the production line is ready for overseas transportation and delivery. All equipment of this cbd production line

is UL certified configuration, explosion-proof configuration ensures safe operation, each process is matched with centrifugal pump or high-precision gear pump, realizes automatic and continuous work between each process, ensures that materials are not polluted, and saves equipment and labor costs. -

-

The equipment involved in the important steps of this production line is briefly described below for your reference

1. Cryogenic ethanol extraction equipment complete set with jacketed stainless steel storage tank and chiller, for alcohol pre-freeze, can reach as low as -80 degrees celsius. Extract from biomass to crude oil.

2. Filtration | dewaxing | winterization process, three stages filtration equipment, high throughput, use for a long time to ensure no clogging. The filter bag and filter element are easy to replace, easy to clean, and low maintenance cost.

3. Evaporation step to recovery ethanol | alcohol, highest efficient rising film evaporator, 200L-1000L wide capacity range.

4. Decarboxylation process, multi function stainless steel jacketed reactor.

5. Two stages molecular distillation equipment to achieve >80% high purity cbd oil.

6. Crystallization reactor to get 99.99% high purity cbd crystals.

7. Drying oven.

8. Matched chiller, heater, vacuum pump, etc.

-

-

CBD production line

, processing equipment customization, we can help you – factory directly sale price | technical support | equipment customization with greatest flexibility | on-site installation & operation training. Contact info@toptionreactor.com

Whatsapp +8613384927293 for details now.