-

How can I improve my heating and cooling efficiency?

The high and low temperature circulation bath

adopts a fully enclosed pipeline design, which is a refrigeration heating and temperature control equipment used in the pharmaceutical and chemical industry, which is energy efficient. -

-

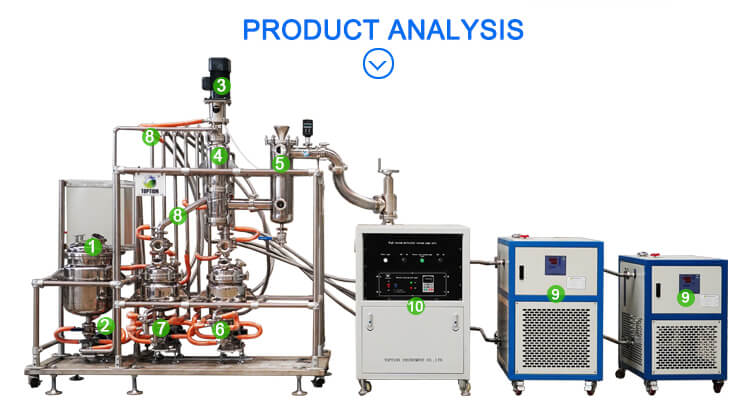

In chemistry reseach, TOPTION high and low temperature circulators bath is applied to the temperature rise and temperature control of molecular distillation equipment

, short path distillation kit, wiped film evaporator, crystallization filter reactor, glass reactor, stainless steel reactor and the bioreactor,etc, temp. control circulating bath is particularly suitable for controlling the heat demand and the heat release process during the reaction process. -

-

Each parts in the heating and cooling circulation bath

is very important. Once the fault occurs, it needs to be solved in time. In the process of running, please pay more attention to the maintenance in time to ensure the efficient operation of the high and low temperature circulating bath.1. Cleaning: Please keep the circulators bath be clean at all times.

2. Anti-rust: Please spray anti-rust oil on the metal surface of the circulators bath’s surface regularly.

3. Lubrication: Please regularly add lubricant to the rotating parts of the machine. If the oil level is lower than 2/3 of the oil sight during operation, should add lubricating oil. If it is polluted or has deteriorated, need to replace the lubricating oil.

4. When not in use for a long time, the heat transfer oil should be drained.

5. When there is sediment at the bottom of the tank, it should be removed in time.

-

-

Start with the details of the device use to improve the heating and cooling efficiency

. More information such as how to choose suitable heater & chiller for your reaction equipment? Want to get lowest price, etc, welcome contact [email protected]

to get technical support.