-

Pharmaceutical engineering is a complex field that requires high precision in every activity, including the purification of chemical substances. One technique that has become increasingly popular in recent years is molecular distillation. Molecular distillation

is a form of distillation where the separation process is based on differences in the molecular weights of the compounds being separated. It is an ideal method for separating heat-sensitive and high molecular-weight compounds from natural products and complex mixtures. -

-

-

Molecular Distillation: An Overview

-

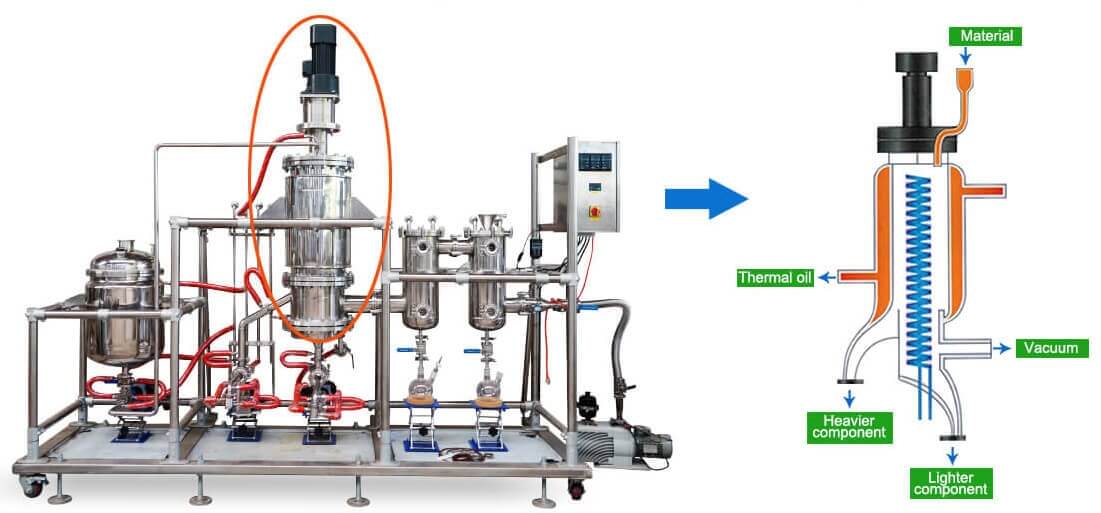

Molecular distillation

is used for the separation of materials that have high boiling points or are thermally unstable. This technique relies on the difference in the boiling points of the compounds being separated. In a molecular distillation setup, the mixture to be separated is heated in a vacuum until the vapors rise to a condenser, where they are cooled and collected.The process of molecular distillation involves the evaporation of a liquid, followed by condensation of the vapors to give a high-purity liquid or solid. It is a highly effective method for separating and purifying materials with high molecular weights and boiling points, such as essential oils, fatty acids, and vitamins. In pharmaceutical engineering, molecular distillation is often used to remove impurities from compounds and maximize their potency.

-

-

-

Advantages of Molecular Distillation in Pharmaceutical Engineering

-

There are many advantages of using molecular distillation

in pharmaceutical engineering. The most prominent advantage is that molecular dist can produce high-purity compounds that are free of contaminants. These are critical pharmaceutical applications where purity and potency are essential. Furthermore, molecular distillation can be used to remove impurities, such as heavy metals, pesticides, and other environmental contaminants from compounds. This ensures that the final product is safe for use in pharmaceutical applications.Another advantage of molecular distillation is that it is a low-temperature technique, which means that it can be used to separate heat-sensitive compounds without damaging their structure or properties. This is critical in the production of pharmaceutical ingredients, where the properties of compounds are key determinants of their efficacy.

-

-

-

Uses of Molecular Distillation in Pharmaceutical Engineering

-

-

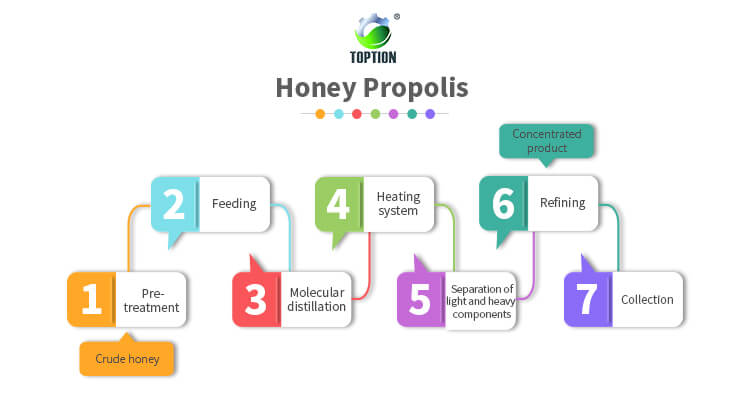

Molecular distillation is used extensively in the pharmaceutical industry for the production of high-purity compounds. One of the most significant applications of molecular distillation in pharmaceutical engineering is the production of active pharmaceutical ingredients (APIs). APIs are the primary compounds responsible for the therapeutic effects of drugs. Thus, the purity and potency of APIs are critical to the effectiveness of the drugs they produce.Molecular distillation is also used in the production of herbal extracts and natural product-based supplements. In this application, molecular distillation is used to remove impurities and maximize the concentration of active compounds in the extract. This results in a more potent and effective product that is free of contaminants.

Molecular distillation is used extensively in the pharmaceutical industry for the production of high-purity compounds. One of the most significant applications of molecular distillation in pharmaceutical engineering is the production of active pharmaceutical ingredients (APIs). APIs are the primary compounds responsible for the therapeutic effects of drugs. Thus, the purity and potency of APIs are critical to the effectiveness of the drugs they produce.Molecular distillation is also used in the production of herbal extracts and natural product-based supplements. In this application, molecular distillation is used to remove impurities and maximize the concentration of active compounds in the extract. This results in a more potent and effective product that is free of contaminants. -

Another key application of molecular distillation in pharmaceutical engineering is the production of omega-3 fatty acids. Omega-3 fatty acids are essential nutrients with many health benefits, including the prevention of heart disease and stroke. However, extracting omega-3 fatty acids from natural sources can be challenging because of their high molecular weight and sensitivity to heat. Molecular distillation is a highly effective method for extracting and purifying omega-3 fatty acids from natural sources, such as fish oil.

-

-

Molecular distillation

is a highly effective method for separating and purifying materials in pharmaceutical engineering. Its ability to produce high-purity compounds, remove impurities, and separate heat-sensitive compounds has made it a critical tool in the production of pharmaceutical ingredients, herbal extracts, and natural product-based supplements. To optimize the use of molecular distillation, pharmaceutical engineers should optimize the conditions for each application and ensure that they maintain the highest standards of purity and potency in their products. Feel free to get in touch with us at [email protected]

.

-